Technology

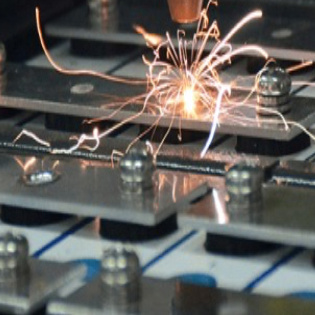

Laser cleaning can replace traditional cleaning methods such as manual mechanical cleaning, chemical cleaning, sandblasting, ultrasonic cleaning, and dry ice cleaning. Laser cleaning has many advantages over traditional cleaning methods.

Non Contact Cleaning & No Cleaning Media

With the high-energy laser beam illuminating on the surface of workpiece, laser cleaning remove oil, rusty and contaminants by selective vaporization.

Green and Environmental

The soot generated during laser cleaning process can be collected by a dust collector, easy to handle, and no secondary products are produced.

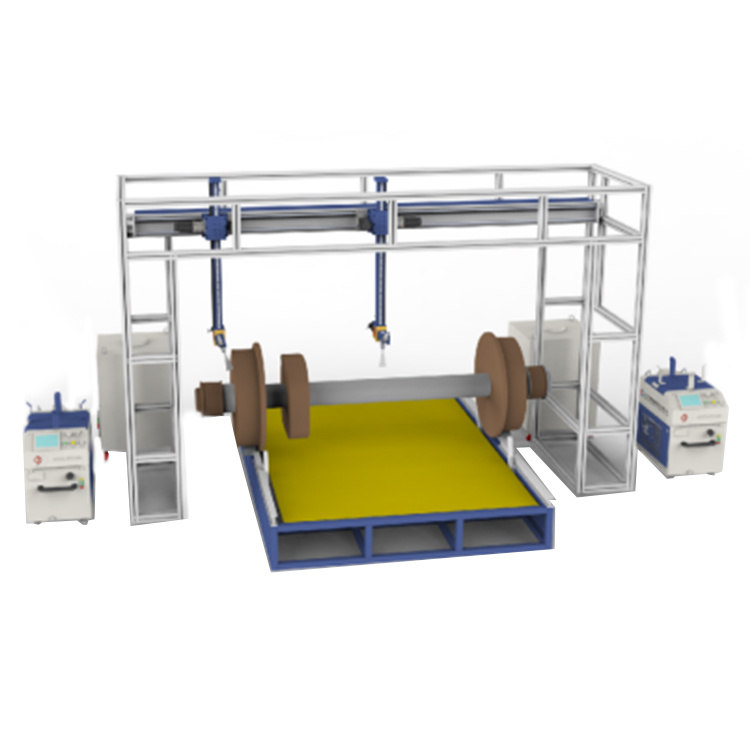

Diversified Operation Modes

Laser cleaning can be divided into hand-held and automatic cleaning.We will customize a solution based on your needs.

Wide Applicability

Laser cleaning can easy remove organic, metal, oxide or inorganic non-metal, which can be widely used in areas such as surface dirt, paint, rust, and film.

Low Operating Costs

Laser cleaning does not use consumables, and operating costs have an advantage over traditional methods.

// ABOUT US

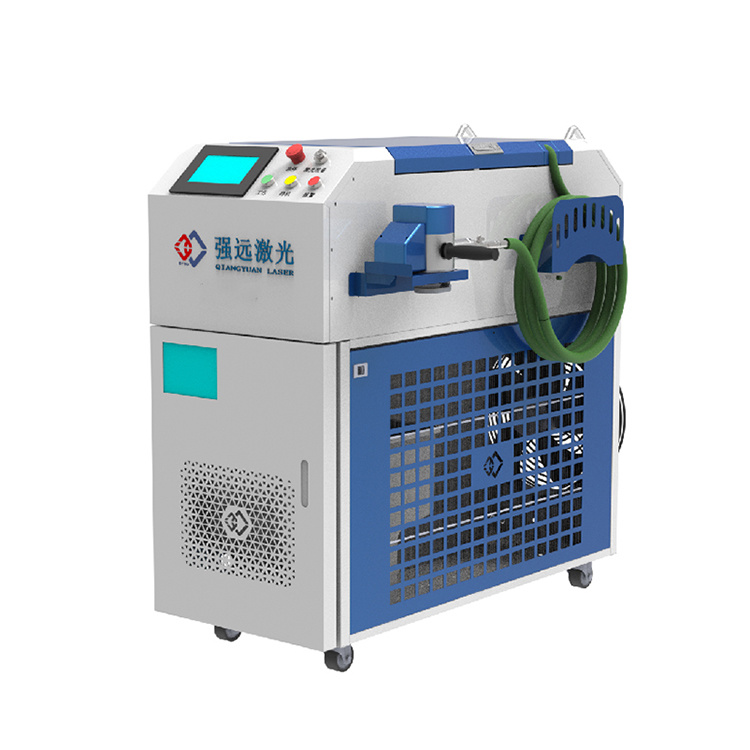

Shandong Qiangyuan Laser of SDIIT Ltd.

Shandong Qiangyuan Laser of SDIIT Ltd. (SDQY Laser) founded by Laser Institute of Shandong Academy of Science since 1978. A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, machines and solutions.

The professional quality and service in the laser industry market have establish a good brand image and reputation.

// PRODUCTS

CHOOSE OUR PRODUCTS

A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, cutting, cladding machines and solutions.

ENTERPRISE STRENGTH

The company relies on the Laser Research Institute of Shandong Academy of Sciences and has a multi-disciplinary high-level R&D and innovation team in optics, mechanics, electronics, etc.

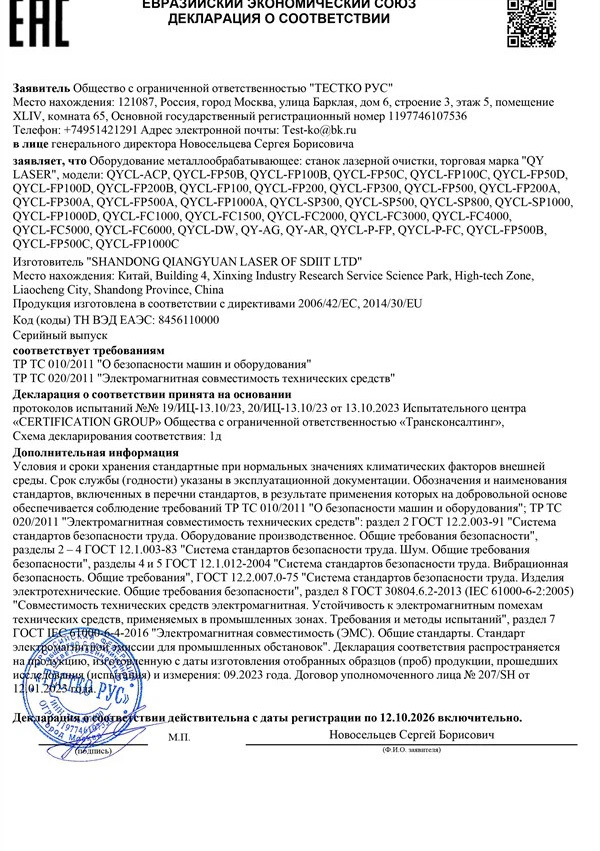

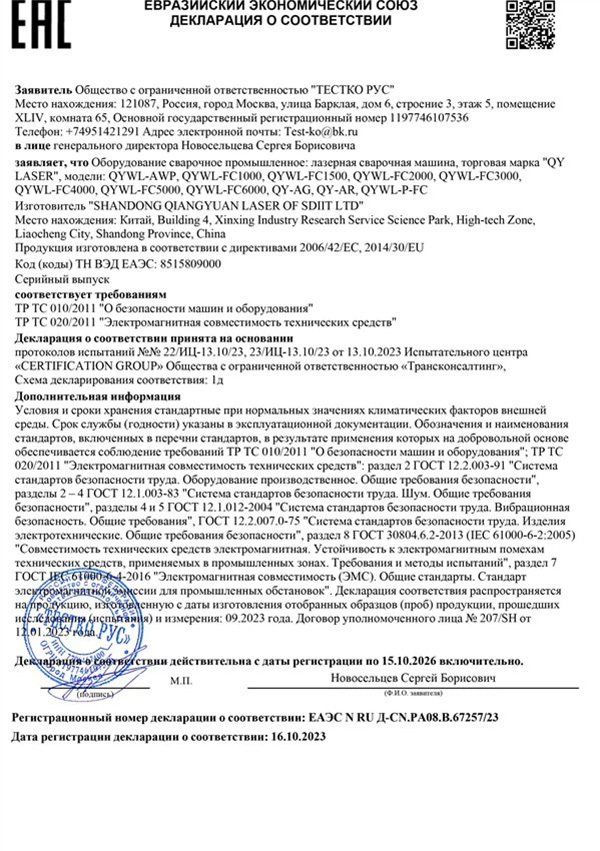

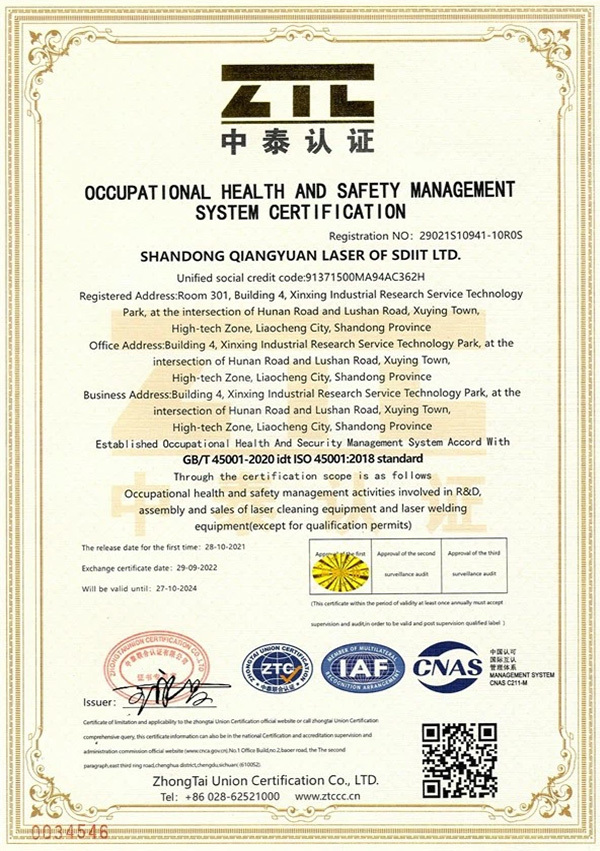

SDQY Laser has passed ISO9001, ISO14001, ISO45001, CE, EAC, FDA, SGS and other certifications.

Provide personalized services in terms of solutions, appearance design, etc. based on customers' specific needs and preferences.

Our after-sales service team have professional skills and knowledge, and can provide accurate and effective solutions in installation guidance, usage training, parts replacement, regular maintenance, etc.

47 years of industry experience

The honors and qualifications received

Exporting countries and regions

APPALICATION

We provided customers with high quality laser solutions.

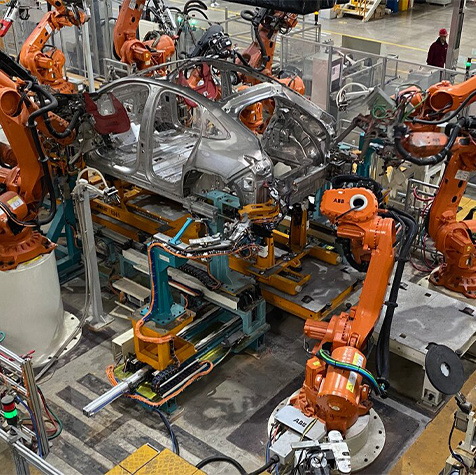

We has more than 50 core independent intellectual property rights at domestic and abroad in laser key core devices, process methods, intelligent control, complete automation solutions. The related products are widely used in aerospace, rail transit, tire mold and other industries.

Aerospace

Rail traffic

Electricity

Cars

Die sheet metal

Other

BLOG

News & Media