Application Of Laser Cleaning Technology in The Automotive Industry

Jul 29,2025

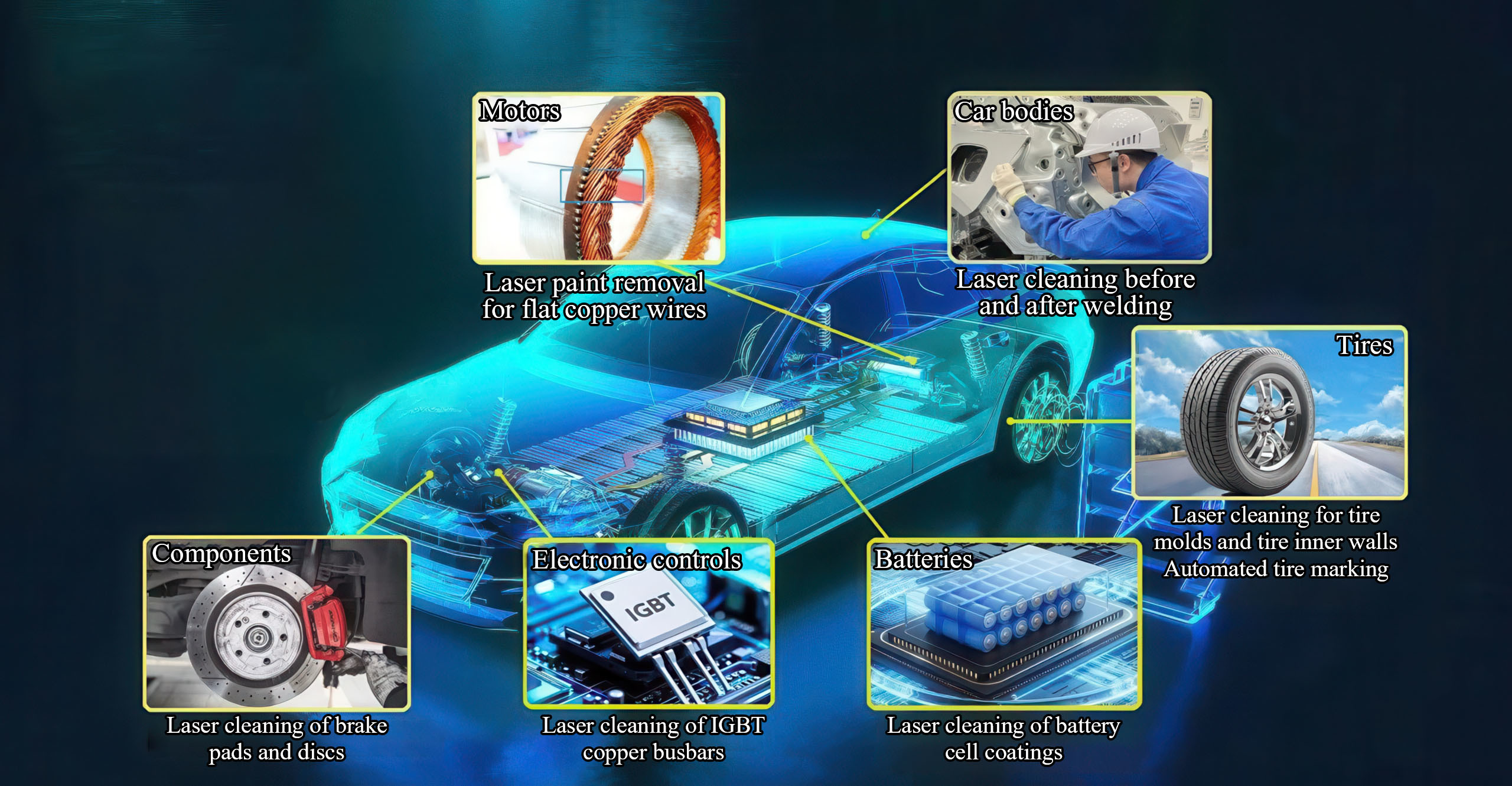

Laser cleaning is known as "the green cleaning technology with the greatest development potential in the 21st century". Compared with traditional cleaning methods, laser cleaning has significant advantages such as green environmental protection, easy automation, high efficiency, high precision and non-contact processing. In recent years, it has been widely used in industrial production, such as automobile manufacturing, aerospace, precision electronics, medical equipment, ships and other fields. In the fields of electric vehicle batteries, motors, electronic controls, car bodies and auto parts, laser cleaning technology has complete application solutions.

1. Laser Cleaning Before and After Welding of Automobiles:

- Remove pollutants such as oil, rust, oxide coating (such as galvanizing), release agent, etc. from welding areas (such as body panels, chassis components, battery trays, etc.). Significantly improve welding quality and strength, reduce welding defects (such as pores, cold welds), and increase welding yield. Cleaning before welding is crucial. Laser cleaning can remove impurities such as oil, dust and oxide layer from welding parts, improve welding quality, reduce welding defects such as pores and slag inclusions, and ensure welding strength and reliability.

2. Automotive Mold Cleaning and Maintenance:

- Removes release agent residue, carbon deposits, polymer residue, oxides, and other residues from the surfaces of stamping, injection, and casting molds. This restores mold surface finish, ensuring product quality (e.g., the surface finish of auto body stamping parts), extending mold life, and reducing downtime for maintenance.

3. Power Battery Manufacturing:

- Pole Cleaning: Removes oil and oxides from the surface of the metal foil (copper foil, aluminum foil) before coating the positive and negative electrodes of lithium batteries to improve the adhesion of the coating slurry.

- Pre-Welding Cleaning: Removes oxides and residual insulation from welding areas such as battery tabs, connectors, and busbars to ensure weld quality and reduce contact resistance.

- Pre-Welding Sealing Pin Cleaning: Cleans the welding area of the battery cover sealing pins to ensure a tight seal.

4. Automobile Parts Cleaning:

- Used to clean the oil and impurities on the surface of engine cylinder, crankshaft, connecting rod and other parts to improve assembly accuracy and performance. Ensure the normal operation of the transmission system and reduce wear and failure. Also, it can remove oil, colloid and rust on the surface of brake discs and brake pads, improve braking performance and ensure driving safety.

5. Automotive Repair and Refurbishment:

- Local Rust/Paint Removal: Precisely removes rust or damaged paint from a vehicle body. Removes oil, carbon deposits, rust, and old coatings from repaired areas such as engine blocks, cylinder heads, and transmission cases, preserving the original metal substrate to the greatest extent possible. Laser cleaning is equipped with a machine vision system to automatically identify rusted areas and plan the optimal scanning path.

6. Automotive Motors:

- Laser paint stripping of flat copper wires: It can effectively and non-destructively strip the paint layer, film coating, PEEK layer, etc. on the surface of the flat copper wires.

7. Automotive Electronic Control:

- IGBT copper busbar laser cleaning: Laser cleaning of semi-finished products after welding ensures that the surface cleanliness of the IGBT chip meets the bonding wire requirements.

8. Automotive Tires:

- Laser cleaning of tire molds, laser cleaning of tire inner walls, and laser cleaning of wheel hubs.

Laser cleaning equipment can not only remove rust, paint, oxide layer, and oil stains from the surfaces of various parts of the car (wheels, brake pads, hoods, engines, etc.), but also has long-term stable use, low operating costs, low maintenance rates, and no other consumables. It can also save a certain amount of labor costs for enterprises, and more importantly, it can easily realize automated operations.

| Comparison items | Laser cleaning | Chemical cleaning | Mechanical polishing |

| Cleaning method | Non-contact laser | Contact chemical cleaning agents | Mechanical/contact sandpaper |

| Workpiece damage | Non-destructive | Damage | Damage-prone |

| Cleaning efficiency | High | Low | Low-cost |

| Consumables | Power-Only | Chemical cleaning agents | Sandpaper, grinding wheel, and oilstone |

| Cleaning effect | High-Cleanliness | General, uneven | Fair, uneven |

| Precise cleaning | Precise and controllable, high accuracy | Uncontrollable, poor precision | Uncontrollable, average accuracy |

| Pollution | No pollution | Environmental pollution | Pollution-prone |

| Manual operation | Simple operation easy automation integration | Complex process, high operational requirements, requiring anti-pollution measures | Time-consuming and labor-intensive, requires anti-pollution measures |

| Cost investment | High initial investment no consumables, low maintenance costs | High initial investment in low consumables | High initial investment, high consumables and labor costs |

With the popularization of high-power pulse cleaning equipment and the maturity of AI control systems, laser cleaning will surely drive automobile manufacturing towards a more efficient, environmentally friendly and intelligent direction, injecting core momentum into the upgrading of the automobile industry.

PREVIOUS: