Laser Cleaning Revolutionizes Wood Surface Treatment: Eco-Friendly Paint Stripping Solutions

Mar 27,2025

Laser cleaning technology redefines the efficiency, precision, and sustainability of wood restoration, offering the industry a game-changing alternative to traditional methods.

For decades, industries such as furniture manufacturing, antique restoration, and architectural conservation have relied on abrasive mechanical methods (e.g., sanding, scraping) or chemical solvents to remove paint and varnish from wood surfaces. While these methods are effective to a certain extent, they also have significant drawbacks:

1. Material damage: Violent mechanical processing can scratch or thin delicate wood grain.

2. Chemical hazards: Solvents release toxic fumes, harm worker health, and generate hazardous waste.

3. Time and labor costs: Manual stripping is labor-intensive and inconsistent, extending project time.

Laser Cleaning: A non-contact, precision cleaning solution

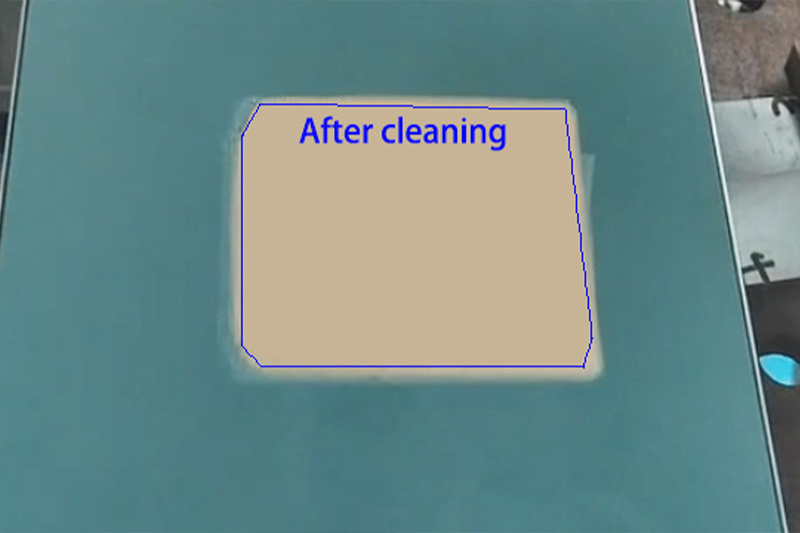

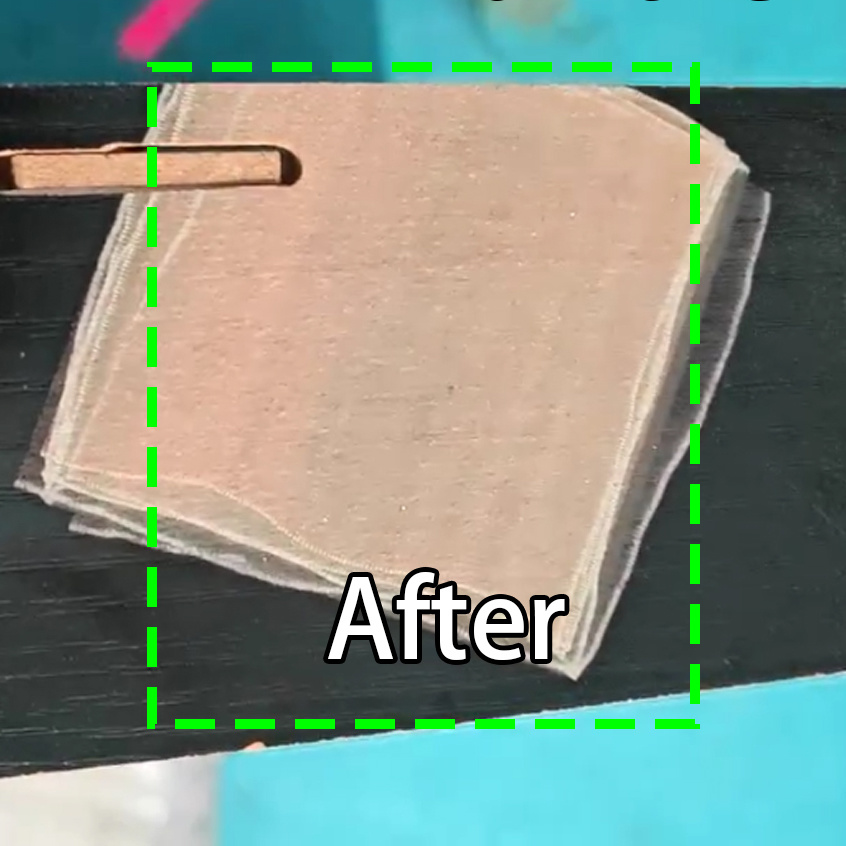

QY LASER's laser cleaning system uses high-intensity pulsed laser ablation to selectively remove paint layers without damaging the underlying wood substrate.

1. Substrate protection: Adjustable wavelength and energy settings ensure compatibility with sensitive wood types.

2. Zero Chemical Use: Eliminates toxic residues and complies with global environmental regulations.

3. Speed and Consistency: Achieve uniform stripping results 3-5 times faster than manual methods.

Cross-Industry Applications

Antique Furniture Restoration: Safely remove centuries-old varnish from antiques without damaging intricate carvings or patina.

Architectural Conservation: Restore historic wood beams, doors and paneling to their original beauty.

Industrial Woodworking: Provide fast, repeatable finishes for mass-produced furniture and flooring.

Technical Specifications

Laser Type: Pulsed Fiber Laser (1060~1070 nm)

Power Range: 100W–1000W (configurable)

PREVIOUS: