About Industrial Laser Cleaning Machine

Mar 25,2025

The industrial sector is experiencing a revolution in surface cleaning and maintenance as laser cleaning machines rapidly gain popularity. These advanced systems utilize high-precision laser technology to provide unparalleled efficiency, safety, and versatility to industries such as aerospace, automotive, and heavy manufacturing. Below, we explore the latest advances and key considerations for companies looking to integrate this groundbreaking technology.

Cutting-Edge Laser Cleaning Solutions

QY LASER’s laser cleaning systems are designed for industrial-scale tasks, such as rust removal and paint stripping of aircraft components, and ensure precise cleaning of aluminum alloy and composite surfaces without damaging the substrate.

Manual Flexibility for Targeted Tasks

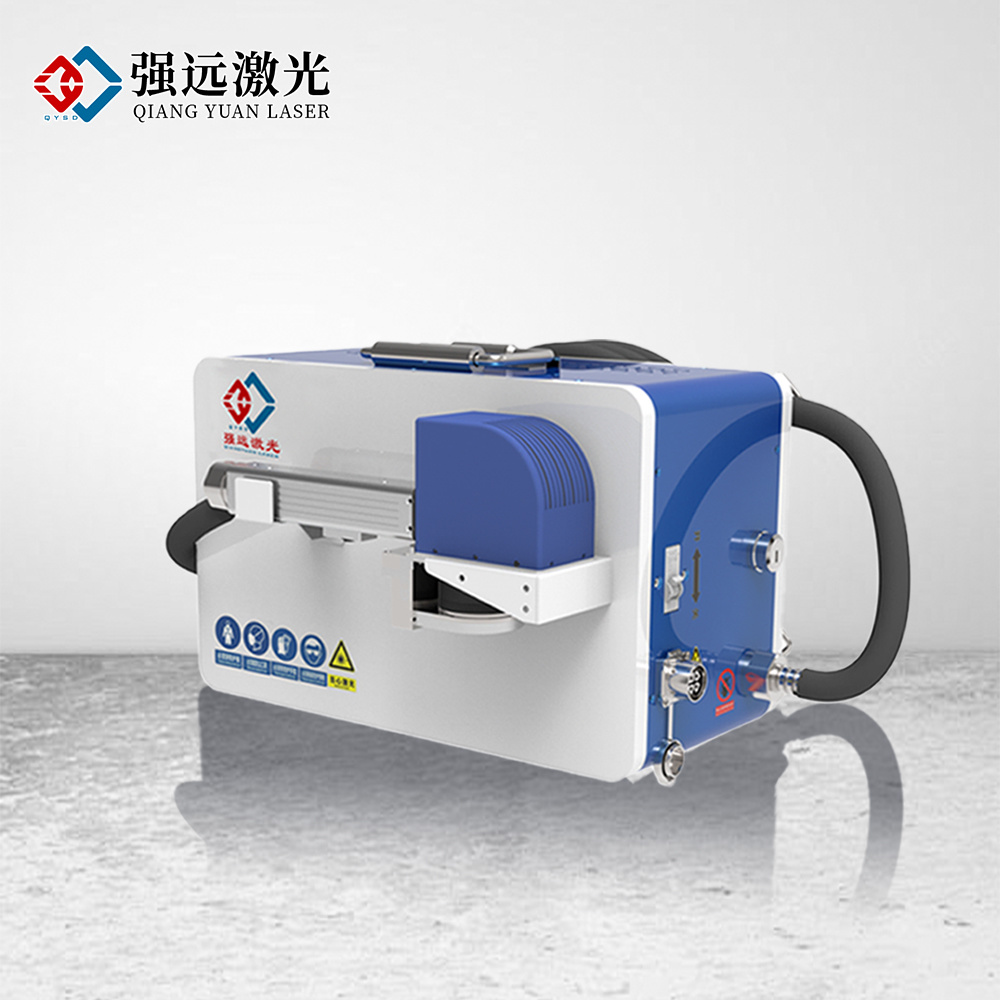

For smaller operations, QY Laser’s QYCL-FP200D offers a 200W portable laser cleaning machine (only 16kg). It features air cooling technology and a compact design, designed for metal parts maintenance, combining economy and low energy consumption.

Why Choose Laser Cleaning?

1. Environmentally Friendly: Eliminating chemical solvents and reducing waste, in line with global sustainable development goals.

2. Non-destructive: Selectively removes contaminants (rust, paint, oil) without abrasive contact, maintaining material integrity.

3. Cost-effective: Minimal consumables and maintenance reduce long-term operating costs.

Verified certifications: Ensure that suppliers meet international standards (e.g. ISO, CE, EAC, FDA certifications).

Customization through OEM: Machines can be customized for specific brands or functional requirements.

Sample testing: We provide free sample testing services before purchase.

Contact us today to learn how laser cleaning can enhance your industrial processes.

PREVIOUS: