There are various cleaning methods in the traditional cleaning industry, most of which use chemical agents and mechanical methods for cleaning. Today, as my country's environmental protection laws and regulations are becoming more and more stringent, and people's awareness of environmental protection and safety is increasing, the types of chemicals that can be used in industrial production cleaning will become less and less. How to find a cleaner and non-destructive cleaning method is a problem we have to consider.

Laser cleaning has the characteristics of non-abrasive, non-contact, non-thermal effect and suitable for objects of various materials. It is considered to be the most reliable and effective solution. At the same time, laser cleaning can solve problems that cannot be solved by traditional cleaning methods. For example, when there are sub-micron pollution particles on the surface of the workpiece, these particles are often sticky and cannot be removed by conventional cleaning methods, but cleaning the surface of the workpiece by nano-laser radiation is very effective. Also, because the laser cleans the workpiece without contact, it is very safe to clean the precision workpiece or its fine parts, and its accuracy can be guaranteed. Therefore, laser cleaning has unique advantages in the cleaning industry.

Laser cleaning is to use pulsed laser to act on the mold, and through mechanisms such as light shock, thermal expansion, vibration, etc., the rubber residue is separated from the mold matrix to achieve the cleaning effect. There is no mechanical contact during the operation process, and the heat input is extremely small and controllable. The substrate is damaged, and sandblasting is a direct mechanical impact, and multiple operations for a long time will cause damage to the mold. At present, some molds cannot be cleaned by sandblasting due to the base material.

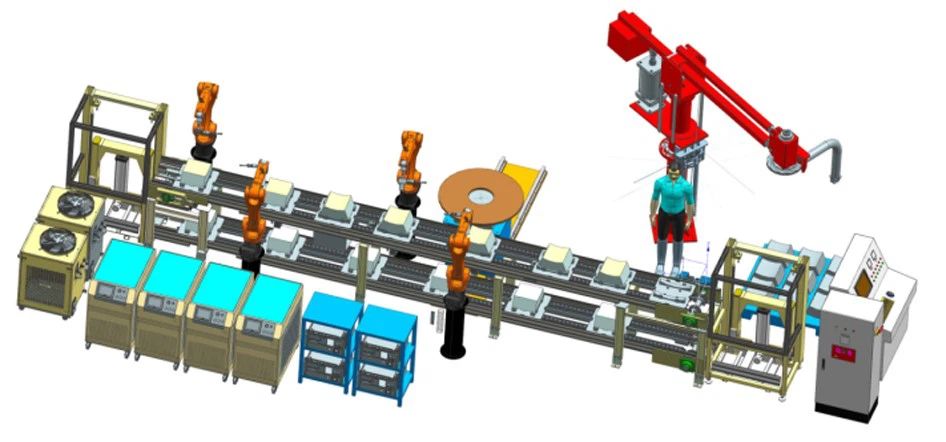

Non-standard automatic tire mold offline laser cleaning system equipment is an automatic equipment specially used for cleaning tire molds. It adopts laser cleaning technology, which can quickly and efficiently clean off the dirt, oil and corrosion substances on the surface without damaging the surface of the tire mold, so as to maintain the good surface quality and functional performance of the mold.

The equipment consists of four parts: double-speed chain assembly line, side shifting and cutting machine, horizontal rotary positioner, laser cleaning system, electrical control system and robot control system and other software organically combined to complete the grinding and polishing of tire molds.

In addition, non-standard automated tire mold offline laser cleaning system equipment can also be customized according to user requirements to meet different cleaning processes and needs and achieve better cleaning effects.

Company Profile

Shandong Qiangyuan Laser of SDIIT Ltd. (SDQY Laser) founded by Laser Institute of Shandong Academy of Science since 1978. A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, cutting, cladding machines and solutions.

Our products has exported to European, American, Middle Eastern, Australian, African countries and regions, we provided customers with high quality laser solutions. The professional quality and service in the laser industry market have establish a good brand image and reputation.

Keywords

Customized Automation Solution -Tire Mold Laser Cleaning System Equipment

Contact Us

Classification