Fully automatic laser cleaning equipment for cleaning large-format composite board

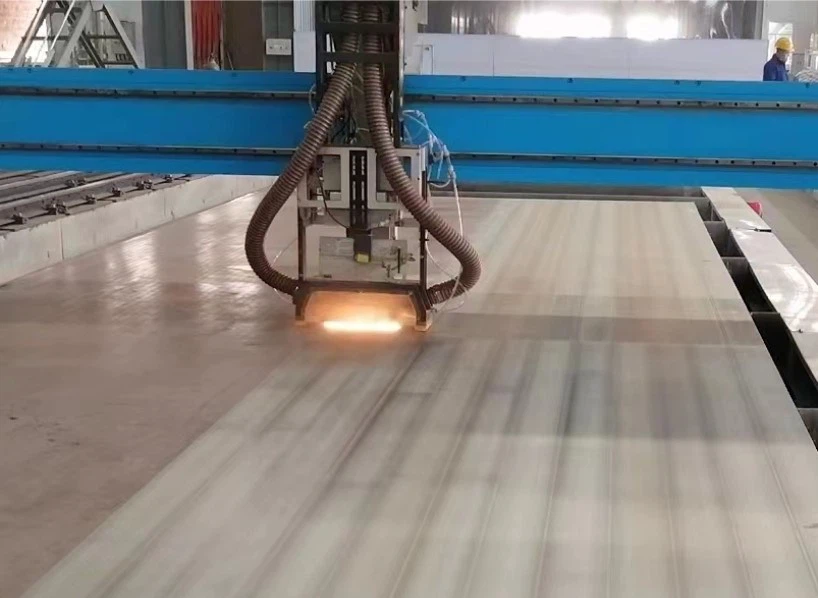

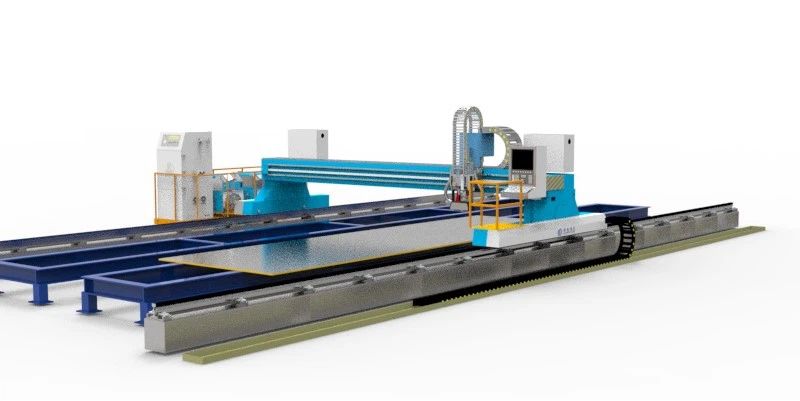

This product is a fully automatic large-format composite board laser cleaning machine that combines CNC numerical control and laser cleaning technology. The laser device adopts dual laser cleaning to combine the cleaning width of the laser through software control of the shutter. The advantage is that the laser line width reaches 260mm and the efficiency is doubled, and the automatic cleaning reduces the use cost and labor cost. The maintenance-free and long-life laser light source ensures the reliability and stability of the equipment.

Features:

● Double-station design is adopted, and the loading, unloading and cleaning of steel plates are correct, which improves the efficiency of equipment use;

● The pattern block and side plate of the flexible mold are cleaned one by one, realizing all-round, multi-angle and full-coverage cleaning;

● The software controls the linear spot to make the overlapping of the two lines more harmonious, effectively improving the cleaning efficiency by 1.5 times;

● The gantry frame structure + CNC numerical control system can precisely control the beam scanning direction of the cleaning head, covering every point on the mold surface, and there is no dead angle in cleaning;

● The laser displacement sensor system enables real-time adjustment of the focal length along with the height of the steel plate to ensure the stability of the laser energy density on the surface of the steel plate and good cleaning consistency;

● Special software for laser cleaning has been developed for composite board cleaning, including cleaning path planning of various specifications, cleaning process parameter expert system and cleaning history data storage;

● Servo control system The uniform speed cleaning control system avoids the "flower (yellow) spot" problem of hand-held cleaning and ensures the tire surface quality;

● Comprehensive safety protection measures, including laser safety protection, mechanical safety protection and smoke and dust collection protection, etc.;

● Equipped with dual-temperature dual-control water temperature cooler, temperature, humidity and wind pressure sensors, real-time monitoring of equipment working conditions and environmental conditions, with good environmental adaptability.

Technical Specifications:

Company Profile

Shandong Qiangyuan Laser of SDIIT Ltd. (SDQY Laser) founded by Laser Institute of Shandong Academy of Science since 1978. A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, cutting, cladding machines and solutions.

Our products has exported to European, American, Middle Eastern, Australian, African countries and regions, we provided customers with high quality laser solutions. The professional quality and service in the laser industry market have establish a good brand image and reputation.

Keywords

Automatic Large Format Composite Board Laser Cleaning Machine

Contact Us

Classification