In the context of Industry 4.0 and smart manufacturing, traditional cleaning methods are highly polluting, inefficient, and prone to damaging workpieces. Laser cleaning, as a green, non-contact process, is an ideal alternative.

However, existing laser cleaning equipment mostly uses traditional robots or gantry structures, which suffer from problems such as bulkiness, complex programming, and difficulties in human-machine collaboration. This makes it difficult to adapt to flexible production of multiple varieties in small batches, and also hinders its flexible application in confined spaces or complex scenarios requiring human-machine cooperation.

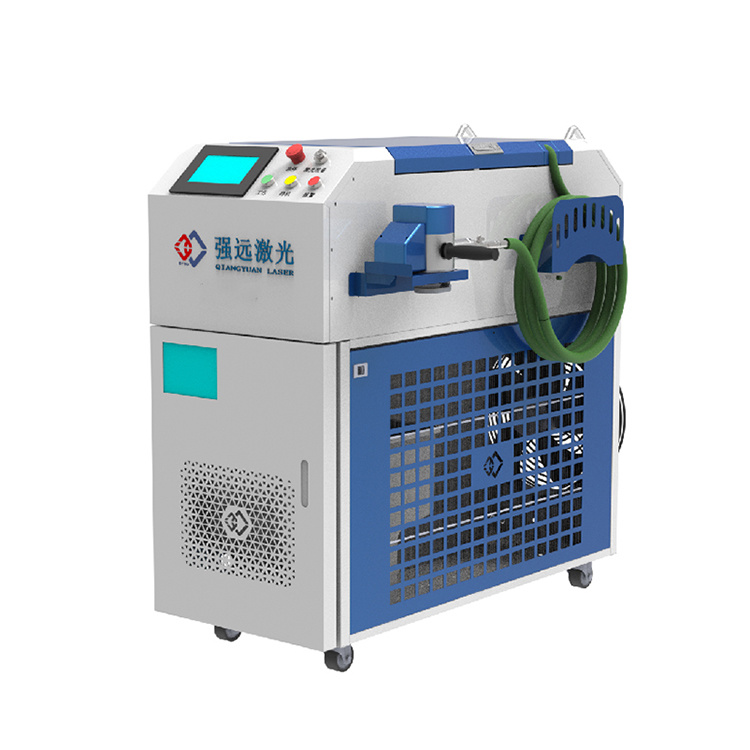

Product Description

The Six-axis Intelligent Control Robot Laser Cleaning Platform is a dexterous collaborative robot laser cleaning platform developed by our company. It integrates machine vision and force control functions, possesses independent intellectual property rights, and enables human-robot collaborative operation. Its application verification in typical flexible scenarios has been completed.

The core principle of this platform can be summarized as follows: a robot with "fine tactile senses," guided by "sharp vision," manipulates a "precise laser blade" to execute cleaning tasks on three-dimensional curved surfaces using the optimal strategy. Its "six-dimensional intelligent control" is key to achieving high-quality, adaptive cleaning.

This dexterous laser cleaning platform, centered on a six-dimensional intelligent control collaborative robot and assisted by 3D camera vision, combines the advantages of robot safety, flexibility, and ease of deployment with the precision and environmental friendliness of laser cleaning. Furthermore, the intelligent recognition of part contours by the 3D camera will greatly expand the application boundaries of laser cleaning technology, providing a revolutionary solution for high-end manufacturing, production line maintenance, and specialized fields.

Key Features

1. High-Degree-of-Freedom Motion Control: Employs an industrial-grade six-axis collaborative robot with flexible spatial movement capabilities, enabling the cleaning of complex curved surfaces, deep holes, narrow crevices, and other areas inaccessible by traditional methods.

2. Non-Contact Cleaning: Laser beams irradiate the workpiece surface, instantly vaporizing or peeling away contaminants (rust, paint, oil, etc.) without physical contact, thus avoiding damage to the substrate.

3. Precision Laser Control System: Equipped with an adjustable pulse/continuous fiber laser, allowing precise adjustment of energy, frequency, and spot size to adapt to different materials (metals, composite materials, etc.) and types of contaminants.

4. Intelligent Process Integration: Integrates 2D/3D vision positioning and online monitoring and analysis, identifying contaminated areas in real time and automatically adjusting cleaning parameters to achieve "adaptive cleaning."

5. Environmentally Friendly and Consumable-Free: Requires no chemical solvents, abrasives, or media, reducing waste disposal costs and meeting green manufacturing standards.

6. Modular Design: Supports expansion modules such as multi-axis positioners, conveyor lines, and dust removal systems, adapting to automated production line integration.

Core Advantages

1. Ultra-high Cleaning Precision and Consistency: The laser can be precisely focused to a micron-level spot, achieving selective cleaning while preserving the integrity of the substrate. The cleaning uniformity is far superior to sandblasting or chemical methods.

2. Non-destructive to Substrate and Extended Lifespan: Non-contact cleaning with a small heat-affected zone avoids deformation, scratches, or residual stress that can occur with traditional cleaning methods, making it particularly suitable for the restoration of precision parts and cultural relics.

3. High Efficiency Automation and Low Labor Costs: The robot path is not only programmable but also equipped with a 6D mouse, supporting offline programming and manual touch teaching. This enables continuous operation on large areas or batches of workpieces, significantly improving efficiency (several times to tens of times faster than manual cleaning).

4. Safety and Ease of Operation: The enclosed workstation is equipped with safety warning lights. Laser energy is transmitted through fiber optics, and the robot is maneuvered flexibly, reducing human contact with hazardous areas or harmful substances.

5. Long-Term Economic Efficiency: Although the initial investment is higher, the lack of consumables, low maintenance, and the long lifespan of the laser source (up to 100,000 hours) make its overall cost lower than traditional processes in the long run.

7.Environmental Adaptability: The ingenious mechanical design and laser cleaning achieve a perfect combination of space and can be used in various confined environments and special scenarios such as cleanrooms. The addition of industrial air conditioning increases equipment stability and reduces failures.

Equipment Structure

Equipment Parameters

1. Robot and Motion Control Parameters:

| Parameters | Target Values for Collaborative Robot |

| Motion Radius | ≥ 1300 mm |

| Repeat Positioning Accuracy | ≤ ± 0.05 mm |

| Maximum End-effector Load | ≥ 12 kg (including cleaning head) |

| Trajectory Accuracy | At rated speed, trajectory tracking error < 1 mm |

| Force Control Sensitivity | Equipped with collision detection function and integrated six-dimensional force sensor, achieving constant force control ≤ 1N |

2. Laser Cleaning Performance Parameters:

| Indicator Item | Technical Parameters | Optional |

| Applicable Laser Power | Compatible with 100W - 500W pulsed fiber lasers | Compatible with 100W - 1000W lasers |

| Cleaning Accuracy (Line Width) | Adjustable from 0.1 mm to 100 mm | Adjustable from 0.05 mm to 150 mm |

| Basic Cleaning Efficiency | Rust removal from Q235 steel surface Paint removal from aluminum alloy surface | |

| Cleaning Consistency/Area | On a flat surface, color difference after cleaning | Maximum cleaning area: 800*675mm |

3. Intelligent System Parameters:

| Indicator Item | Technical Parameters | Optional |

| Path Planning Speed | Automatic cleaning path generation after drag-and-drop recognition: < 30 seconds | Visual Recognition |

| Process Database | Built-in process packages for ≥ 3 materials (steel, aluminum, composite materials) and ≥ 2 contaminants (paint, rust) | Process parameter self-learning and optimization functions |

4. Overall Machine and Safety Specifications:

| Indicator Item | Technical Parameters | Optional |

| Total Power Consumption | < 3 kW (under full load) | |

| Mean Time Between Failures (MTBF) | MTBF ≥ 1000 hours | A core indicator reflecting reliability |

| Laser Operation Alarm | Tri-color Indicator (Red for alarm, Yellow for standby, Green for operation) | Red, Yellow, Green Indicator |

| Noise Level | Operating Noise ≤ 75 dB | Includes dust removal system operating noise |

The Value We Offer

- Customized cleaning processes tailored to your specific workpieces and stain types.

- Comprehensive technical training and process debugging to ensure rapid deployment.

- Professional after-sales and remote diagnostic services to guarantee long-term stable equipment operation.

FAQ

Q1: Does this equipment require a dedicated dust collection system?

A: If needed, we will configure suitable dust collection equipment for you to ensure a clean working environment.

Q2: Does it support flexible production of small batches and multiple product varieties?

A: It supports quick parameter switching, suitable for flexible cleaning tasks.

Q3: Do operators need to have a background in laser or robotics?

A: No. We provide a graphical user interface; ordinary workers can operate it after training.

Company Profile

Shandong Qiangyuan Laser of SDIIT Ltd. (SDQY Laser) founded by Laser Institute of Shandong Academy of Science since 1978. A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, cutting, cladding machines and solutions.

Our products has exported to European, American, Middle Eastern, Australian, African countries and regions, we provided customers with high quality laser solutions. The professional quality and service in the laser industry market have establish a good brand image and reputation.

Keywords

Six-axis Intelligent Control Robot Laser Cleaning Platform

Contact Us

Classification