Aluminum alloy materials are widely used in the aviation industry due to their light weight and outstanding mechanical properties, especially in stress structural parts such as bulkheads and wing beams of large passenger aircraft and new energy battery structural parts. Laser cleaning of the oxide film on the aluminum alloy while minimizing damage to the aluminum alloy substrate puts high demands on the cleaning rate of the oxide layer on the surface of the parts and the surface roughness of the parts.

Laser cleaning is environmentally friendly, widely applicable, highly precise and effective, and can replace traditional physical grinding and chemical cleaning methods to improve the cleaning quality of structural parts. It is especially effective in cleaning welds at the welding position of aluminum alloy materials.

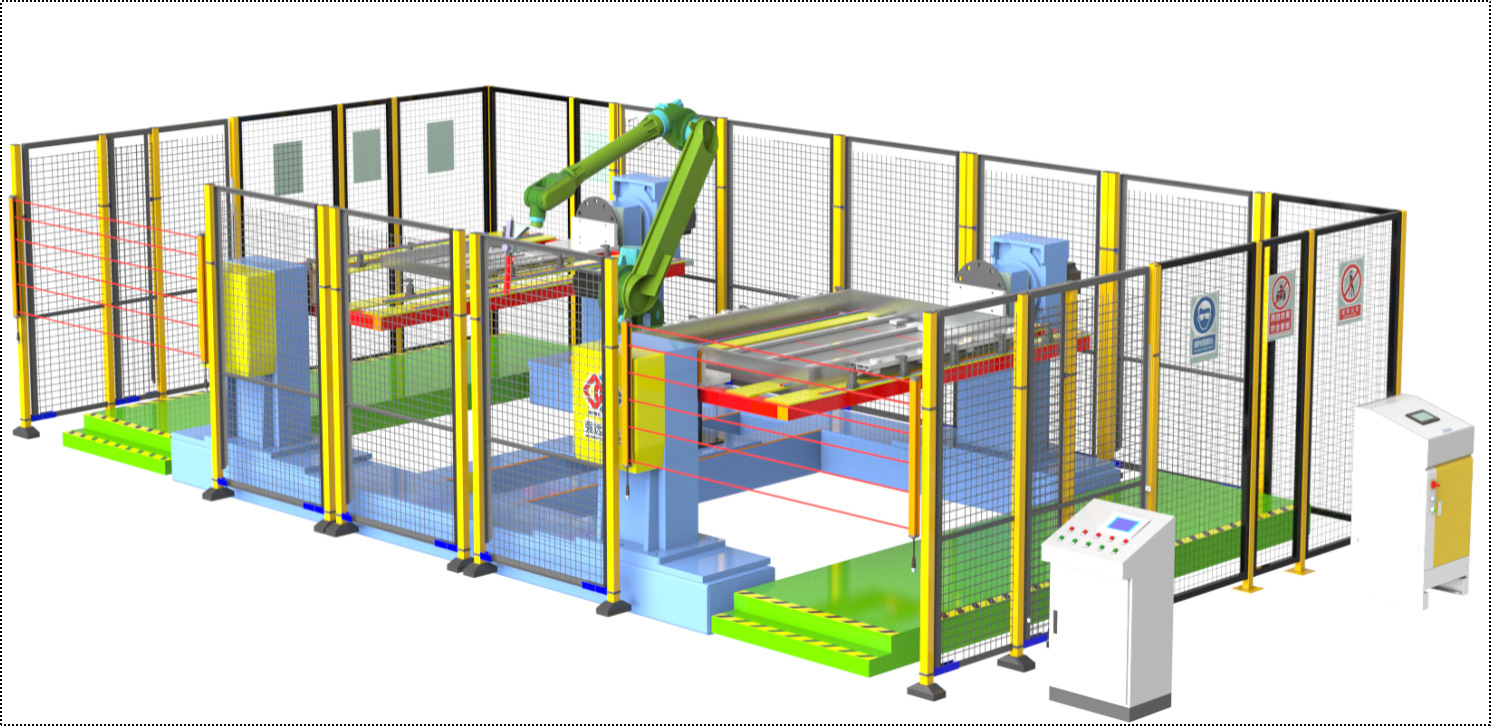

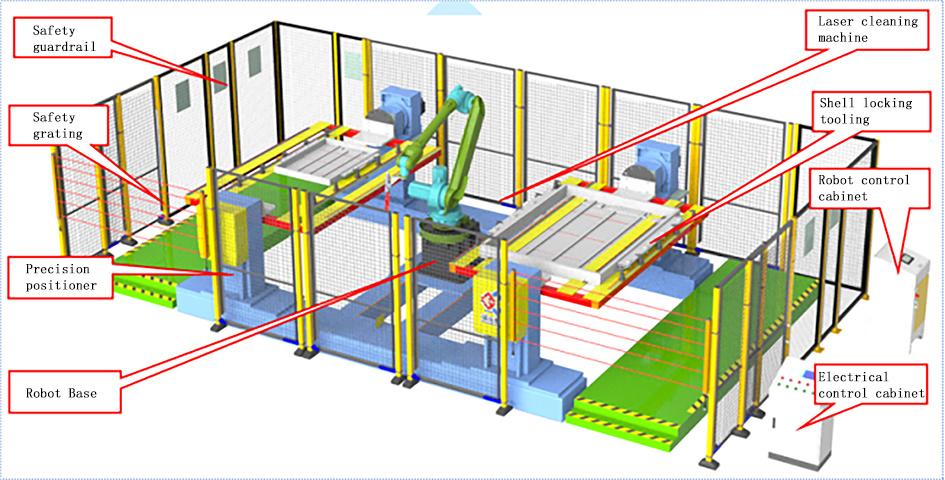

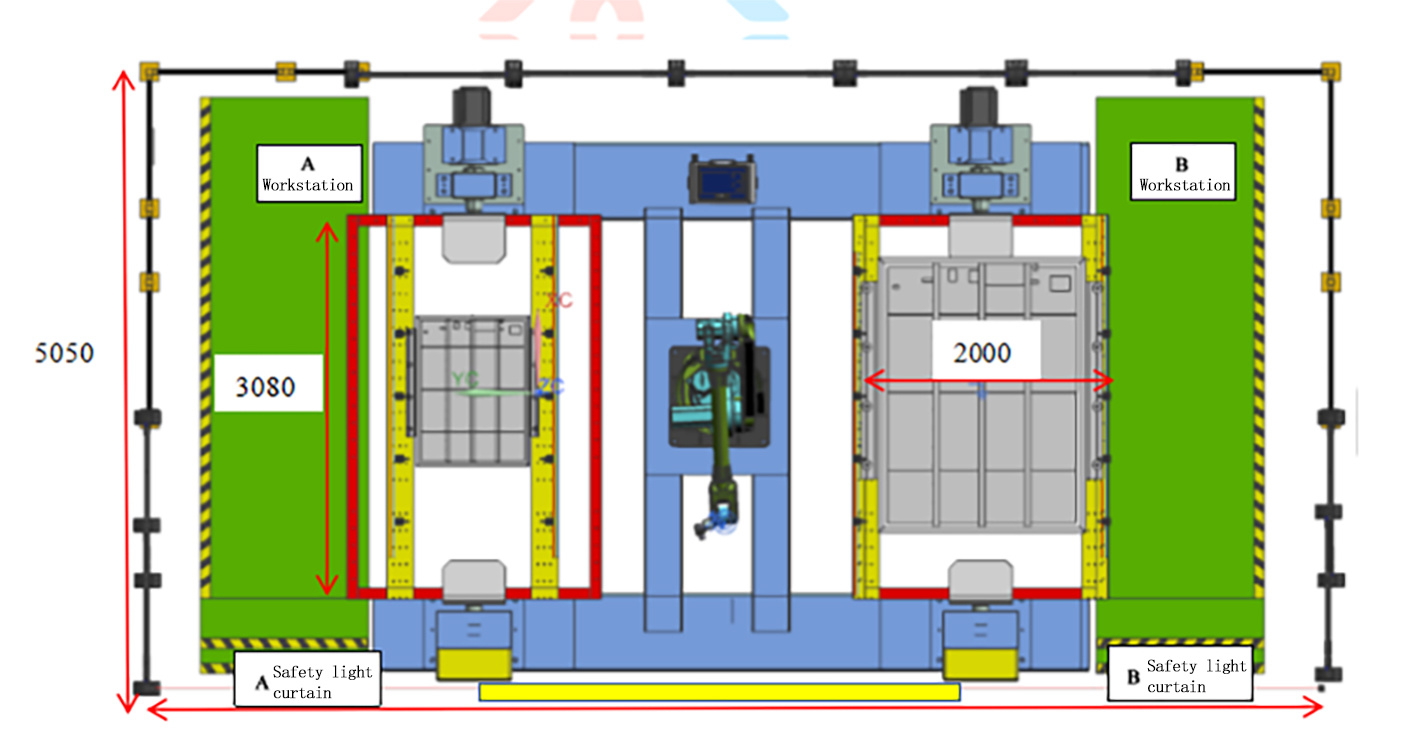

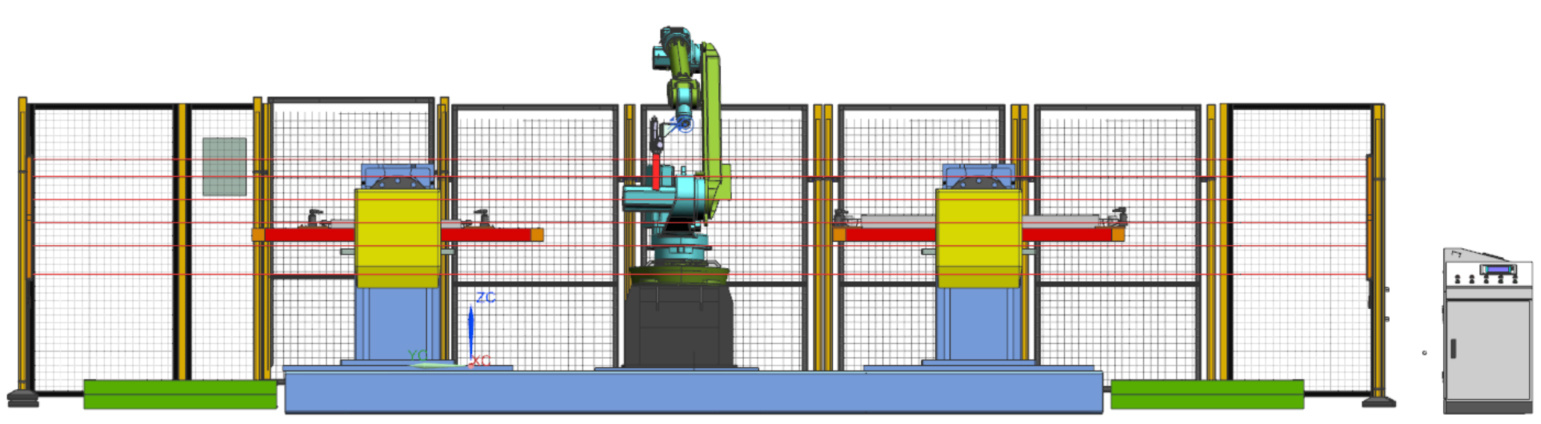

The lithium battery shell laser cleaning workstation adopts an integrated H-shaped frame, and the robot positioner is installed on the middle beam of the frame. The positioner adopts a double-opposing positioner layout, and the positioner is a flip positioner. It uses an adjustable tooling frame with a length clearance of 3080mm, which can cover the cleaning of 2200*1800mm products.

The outside of the equipment is equipped with a safety guardrail and a safety grating. After manual loading is completed, the equipment can only be operated after the personnel have walked out of the grating range, ensuring the safety of equipment operation.

Equipment Parameters

| No. | Name | Model | Quantity(Unit) | Brand |

| 1 | Customized industrial robots | QYLT2950-30kg | 1 | QIANGYUAN LASER |

| 2 | Precision double support positioner | QYJM-D3080 | 2 | QIANGYUAN LASER |

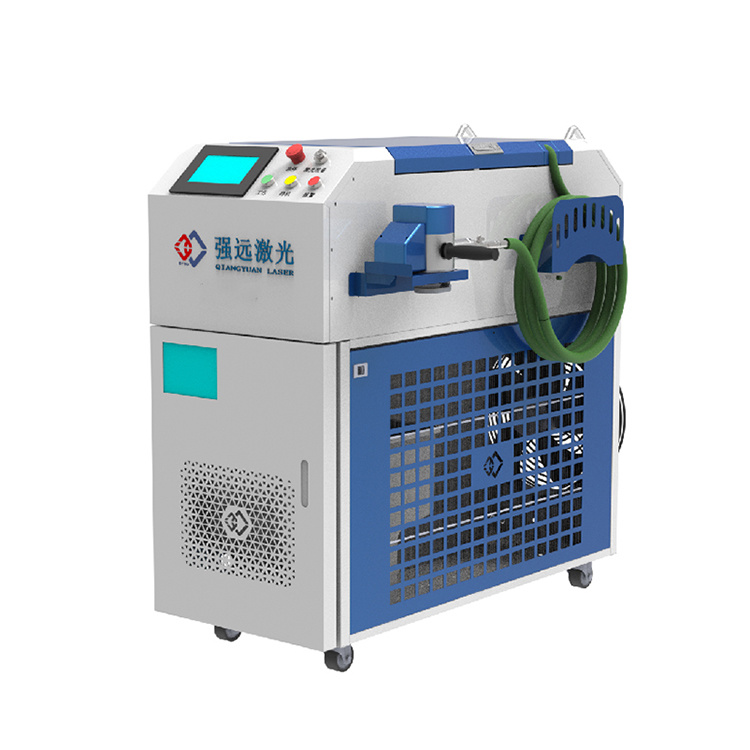

| 3 | Pulse laser cleaning machine | QY-FP200 | 1 | QIANGYUAN LASER |

| 4 | Shell locking tool | QY-SJGZ2 | 2 | QIANGYUAN LASER |

| 5 | Robot base | 900*900*500 | 1 | QIANGYUAN LASER |

| 6 | Cleaning head fixing tool | Customized | 1 | QIANGYUAN LASER |

| 7 | Foot platform | Customized | 2 | QIANGYUAN LASER |

| 8 | Electrical control cabinet | 1 | QIANGYUAN LASER | |

| 9 | Safety fence | 3800*3800*2000 | 1 | QIANGYUAN LASER |

| 10 | Safety light curtain | 2 | QIANGYUAN LASER | |

| 11 | Electrical accessories | 1 | QIANGYUAN LASER |

Structure

The lithium battery shell laser cleaning workstation system equipment mainly includes: customized industrial robot system, precision double-support positioner, QY-FP200 pulse laser cleaning machine, shell locking tooling, robot base, QY-FC200 series cleaning head and cleaning head fixing tooling, electrical control cabinet, dust collection system (optional), safety guardrail and safety grating, etc.

Equipment Layout

Equipment Size Top View

Equipment Dimensions Left View

Core Advantages, Leading the "Clean" World

No contact, zero damage: The laser energy acts precisely on the surface pollutants (oil, dust, oxides, release agents, etc.) of the shell, completely avoiding scratches and deformation caused by physical contact, perfectly protecting the integrity of the shell, and ensuring battery safety and performance.

Clean and residue-free: Laser cleaning completely removes micron-level residues by instantly vaporizing or stripping pollutants, achieving extremely high cleanliness standards (such as increased dyne value), and significantly improving the yield and reliability of subsequent processes (such as welding, gluing, and encapsulation).

High Efficiency and Energy Saving, Cost Reduction and Efficiency Improvement

- Cleaning in seconds: The laser scanning speed is fast, the cleaning time of a single piece is greatly shortened, and the production line rhythm is significantly improved.

- No consumables required: Say goodbye to chemical solvents, abrasives, wiping cloths and other continuous consumables, greatly reducing operating costs.

- Maintenance-free design: The core laser has a long life, the workstation design is stable and reliable, and downtime is reduced.

- Green and environmentally friendly, safe and worry-free:

- No chemical pollution: Completely eliminate VOC emissions and harmful waste liquid treatment problems to create a green factory.

- Controllable dust: Integrated high-efficiency dust removal system, effectively collect and treat trace aerosols generated by cleaning, to ensure a clean working environment and workers' health.

- Low energy consumption: Compared with traditional high-pressure water guns or large chemical cleaning lines, energy consumption is significantly reduced.

- Highly automated and intelligent:

- Flexible integration: It can be easily integrated into automated production lines (robot loading and unloading, conveyor belt docking) to achieve unmanned operation.

- Intelligent control: Equipped with advanced visual positioning system, accurate identification of workpiece position and cleaning area; digital management of process parameters to ensure consistency of cleaning effect.

- Process traceability: Record cleaning process parameters to meet quality traceability requirements.

- Widely applicable: Suitable for surface cleaning of various lithium battery metal shell materials (aluminum, steel, copper, etc.) such as square aluminum shell, cylindrical steel shell/aluminum shell, blade battery shell, etc.

Create Core Value for You

- Improve product quality: Clean surface = higher welding/bonding yield = more reliable battery safety and performance.

- Reduce overall costs: Save consumables, energy consumption, waste liquid treatment and labor costs, and quickly recover investment.

- Accelerate production rhythm: Meet the needs of high-speed production lines and improve overall production capacity.

- Practice green manufacturing: Comply with increasingly stringent environmental regulations and enhance the image of corporate social responsibility.

- Enhance process stability: Digital and automated control eliminates interference from human factors and ensures batch consistency.

Technical Highlights

- Precision optical system: High-precision galvanometer to achieve μm-level precision cleaning path control.

- Customized laser source: Optimize wavelength and pulse parameters to achieve the best cleaning effect for different pollutants and substrates.

- Modular design: Flexible configuration according to customer production capacity, space and budget.

- Human-machine friendly interface: Easy operation, intuitive parameter setting, and clear status monitoring.

Application Scenarios

- Cleaning of lithium battery cell shell before welding

- Cleaning of battery module/PACK shell before assembly

- Cleaning of battery shell repair/refurbishment

The lithium battery shell laser cleaning workstation is not only an upgrade of the cleaning equipment, but also a key step towards efficient, intelligent and green lithium battery manufacturing!

Company Profile

Shandong Qiangyuan Laser of SDIIT Ltd. (SDQY Laser) founded by Laser Institute of Shandong Academy of Science since 1978. A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, cutting, cladding machines and solutions.

Our products has exported to European, American, Middle Eastern, Australian, African countries and regions, we provided customers with high quality laser solutions. The professional quality and service in the laser industry market have establish a good brand image and reputation.

Keywords

Lithium Battery Shell Laser Cleaning Workstation

Contact Us

Classification