Products Description

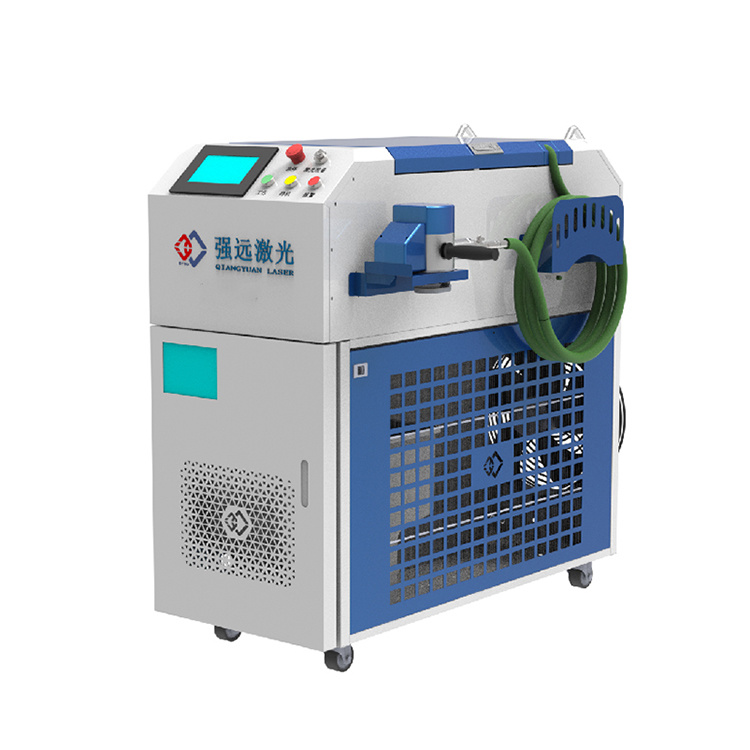

Desktop 3-Axis Laser Cleaning Device --- An Intelligent Solution for Cleaning Small Parts!

In the fields of precision machining, electronic manufacturing, 3C industry, etc., batch cleaning of small workpieces has always faced problems such as low efficiency, large damage, and poor environmental protection. Traditional cleaning methods (such as chemical cleaning and sandblasting) are not only costly, but may also affect product accuracy.

The desktop 3-axis laser cleaning device is specially designed for batch cleaning of small parts. It uses a high-precision three-axis module + intelligent laser cleaning head to achieve efficient, non-destructive, and fully automatic cleaning, making your production smarter and more environmentally friendly!

Advantage

Why Choose the Desktop 3-Axis Laser Cleaning Device?

1. High efficiency in batches, doubled production capacity

The workbench structure design, equipped with a high-precision three-axis motion system (X/Y/Z axis), can be programmed to run automatically, supports multi-workpiece array cleaning, and is much more efficient than manual work!

It is suitable for rapid deoxidation, degreasing, and paint removal of small metal/non-metal parts (such as electronic components, precision gears, hardware, ceramic substrates, etc.).

2. Non-contact cleaning, zero damage

The laser energy is precisely controllable, only removing stains and oxide layers without damaging the substrate, especially suitable for the cleaning needs of high-precision, fragile small parts.

3. Environmental protection and energy saving, saving consumables

No chemical solvents, no dust pollution, say goodbye to the wastewater and exhaust gas problems of traditional cleaning, meet green manufacturing standards, and reduce environmental protection treatment costs.

4. Intelligent control, one-button start

Customizable cleaning path, adjustable parameters (power, speed, cleaning pattern), to meet the needs of different materials. Simple operation, novices can quickly get started, saving training costs!

Application Scenarios

3C electronics: cleaning of PCB boards before welding, degreasing of metal parts of mobile phones.

Precision hardware: rust removal of micro bearings, gears, and screws.

Auto parts: cleaning of oxide layers of sensors and connectors.

Mold industry: cleaning of release agent residues of small injection molds and stamping molds.

Equipment Parameters

Laser type: fiber laser (50W-500W optional, suitable for different cleaning needs).

Working area: 300×300mm to 300×600mm (standard), support customization of larger size.

Cleaning mode: 2D cleaning head, supports multiple graphic transformations to adapt to different workpiece types.

Cleaning speed: adjustable speed, supports high-speed mode batch processing.

Company Profile

Shandong Qiangyuan Laser of SDIIT Ltd. (SDQY Laser) founded by Laser Institute of Shandong Academy of Science since 1978. A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, cutting, cladding machines and solutions.

Our products has exported to European, American, Middle Eastern, Australian, African countries and regions, we provided customers with high quality laser solutions. The professional quality and service in the laser industry market have establish a good brand image and reputation.

Keywords

Desktop 3-Axis Laser Cleaning Machine

Contact Us

Classification