Technical advantages

1. High precision and consistency

Grinding machines and vertical machining centers have micron-level machining accuracy. With the help of robot automatic loading and unloading, human errors can be eliminated. They are especially suitable for mass production of high-precision parts (such as aerospace blades, precision molds, etc.).

2. Efficiency improvement

Robots work continuously for 24 hours, reducing machine standby time, stabilizing the processing rhythm, and improving production efficiency by 30%-50% (depending on the complexity of the workpiece).

The multi-axis linkage capability of the vertical machining center combined with the robot can realize multi-process integration (such as loading and unloading, flipping, and testing), reducing transfer time.

3. Flexible production

Through rapid switching of robot programs (or visual guidance), the same system can adapt to multi-variety and small-batch orders to meet the rapid production change needs of industries such as automobiles and 3C. Modular design supports future expansion (such as adding AGV logistics or collaborative robots).

4. Cost optimization

1) Reduce manual dependence and reduce labor costs in the long term;

2) Reduce material waste through precise control (such as grinding wheel loss optimization of grinders).

5. Safety and reliability

1) Robots replace manual processing of heavy workpieces (such as car wheels) or dangerous processes (such as high-temperature parts), reducing the risk of work-related injuries;

2) Equipped with force control sensors and anti-collision systems to ensure equipment safety.

Key application industries

1. Automobile manufacturing

Application scenarios: Grinding and milling of high-precision parts such as engine cylinders, gearbox gears, and brake discs.

Demand drive: The demand for processing lightweight parts (such as aluminum alloy motor housings) in new energy vehicles has surged.

2. Aerospace

Typical workpieces: high-temperature alloy parts such as turbine blades and landing gears, which rely on the precision polishing of grinders and the five-axis linkage of machining centers.

Trend: The demand for automated processing of composite materials has increased.

3. Energy equipment

Case: Batch processing of wind power gearboxes and hydraulic valve blocks, robots can handle large-size workpieces (requires large load models).

4. Mold industry

Advantages: The automation system solves the problem of repeated positioning in the processing of high-hardness materials such as mold steel.

Market Prospect Analysis

1. Growth Drivers

Labor shortage and rising costs: The average wage of Chinese manufacturing workers has increased by 8%-10% annually, forcing enterprises to transform themselves into automated ones.

Industry 4.0 policy support: Government subsidies for smart manufacturing (such as China's "14th Five-Year Plan" smart manufacturing plan) have accelerated the penetration rate.

Technology maturity: The popularity of collaborative robots has lowered the threshold for automation, and force control technology has further expanded its application scenarios.

2. Challenges

High initial investment: A set of medium-sized automation units (grinders/machining centers + robots) has high costs, and the decision-making cycle of small and medium-sized enterprises is long.

Process adaptation complexity: The loading and unloading of special-shaped workpieces (such as curved blades) requires customized fixtures or 3D visual assistance, which is difficult to implement.

3. Future trends

Digital twins and AI optimization: Virtual debugging shortens deployment time, and AI algorithms predict tool wear and optimize robot paths.

Human-machine collaboration upgrade: Lightweight robots directly participate in precision assembly (such as electric spindles on the wrist).

Sub-segment explosion: Semiconductor equipment and medical implant processing will become new growth points.

Recommended implementation strategy

Priority scenario: Start from processes with high repetitiveness and high risk of work-related injuries (such as heavy workpiece handling), and the ROI return cycle will be shorter.

Supplier selection: Pay attention to system integrators with machine tool-robot collaborative control capabilities (such as DMG + KUKA solutions).

Phase-based implementation: First automate a single machine, then gradually connect the MES system to achieve full workshop intelligence.

The penetra·tion rate of this technology combination in high-end manufacturing is expected to grow at an average annual rate of 15%-20% in the next five years, especially in the fields of new energy vehicles and aerospace, where it will become standard. Enterprises need to combine their own process pain points and choose solutions that balance flexibility and precision.

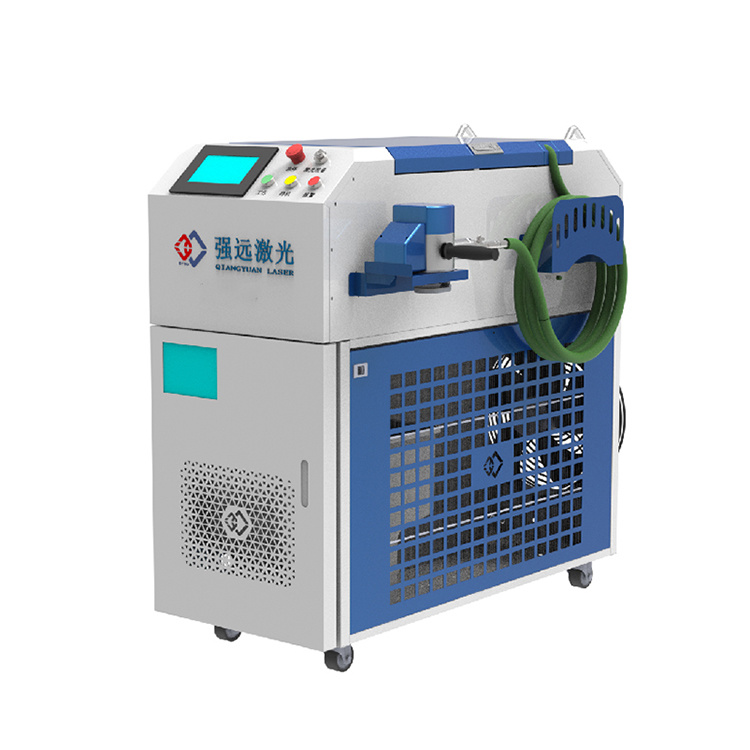

Company Profile

Shandong Qiangyuan Laser of SDIIT Ltd. (SDQY Laser) founded by Laser Institute of Shandong Academy of Science since 1978. A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, cutting, cladding machines and solutions.

Our products has exported to European, American, Middle Eastern, Australian, African countries and regions, we provided customers with high quality laser solutions. The professional quality and service in the laser industry market have establish a good brand image and reputation.

Keywords

Grinding Machine/Vertical Machining Center, Robot Automatic Loading And Unloading

Contact Us

Classification