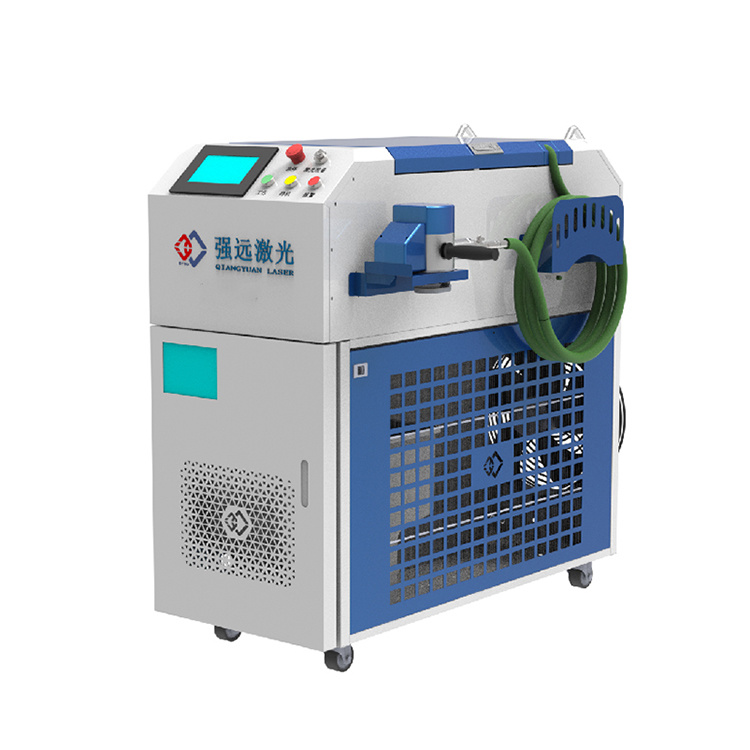

Equipment Introduction

The composite laser cleaning machine integrates continuous laser and pulse laser, and has the advantages of continuous laser large-area cleaning and pulse laser suitable for clearing stubborn stains. It has higher overall efficiency, can adapt to a variety of cleaning needs, and is widely used in multiple industrial fields. It is superior to single continuous or pulse laser cleaning in terms of efficiency, applicability, cleaning effect, substrate protection, flexibility and economy. It can meet more diverse cleaning needs and is an ideal choice for modern industrial cleaning.

Equipment Features

1. Cleaning efficiency: The advantages of laser composite cleaning technology are not just the superposition of two lasers. The key is that the energy utilization rate is far greater than the simple addition of two heat sources. It comprehensively utilizes the characteristics of continuous laser stability, continuity, and high average energy, as well as the instantaneous penetration and accuracy of pulse laser to achieve a combined effect of 1+1>2.

2. Applicable scenarios: It is suitable for thick coatings and heavy rust that cannot be removed by conventional laser cleaning, and does not damage the substrate. It has outstanding advantages in wheel set cleaning applications.

3. Automated cleaning: The laser cleaning process is automated through an automated system (joint or truss robot), which improves cleaning efficiency, consistency and precision and reduces manual intervention.

4. Protection of optical devices: The field mirror is designed with two layers of protective lenses to prevent dust or debris from contaminating the optical system and extend the service life of the equipment.

5. Dust collection and wind knife: The end is equipped with a semi-enclosed dust collection port, which can remove 90% of the smoke and dust to ensure a clean working environment; the high-speed airflow generated by the wind knife removes the dust generated during the cleaning process to prevent contamination of the lens.

Application

- Aerospace Industry

In aviation, laser cleaning is applied to remove paint and coatings from aircraft surfaces.

- Military Equipment Maintenance

The technology is employed for rust removal, decontamination, and selective cleaning of weapons and military vehicles. It enhances maintenance efficiency while avoiding chemical waste, aligning with strict environmental and safety standards.

- Automotive and Mold Cleaning

In automotive manufacturing, laser systems clean tire molds, engine components, and coatings. For instance, use it to remove residues from rubber molds, improving production quality and reducing downtime.

- Railway and Shipbuilding

Laser cleaning replaces traditional sandblasting in rail track preparation (e.g., removing oxides before welding) and ship surface treatment, reducing dust pollution and improving operational safety in compliance with environmental regulations.

- Industrial Manufacturing

Applications include pre-weld cleaning of metals (e.g., aluminum, titanium alloys) and post-processing in electronics, such as oxide removal from circuit board components, ensuring high precision and minimal thermal impac.

- Cultural Heritage Conservation

Laser cleaning has been extensively used in Europe since the 1990s for restoring historical artifacts, sculptures, and architectural structures (e.g., churches, castles). It offers non-damaging removal of pollutants and coatings without harming delicate surfaces, making it ideal for preserving cultural heritage.

About Us:

- Class 1000 clean rooms

- R&D Test Center

- 50+ independent intellectual property rights

- Serving global customers in 30+ countries/regions

Core competitiveness:

✔️ Independent research and development of cleaning system and gun head

✔️ Customized automation integration

Why choose us?

🏆 Laser Research Institute of Shandong Academy of Sciences

🔧 72-hour global technical support response

⚡ Delivery speed is 20% faster than the industry average

Technical support hotline: +86-18663512279

Export certification: CE, FDA, EAC, ISO, SGS

Submit Your RFQ

📧 Email: sdqylaser@sdqy-laser.com

📱 WhatsApp: +86-17362295086

Online Form: www.sdqy-laser.com/contact-us

Company Profile

Shandong Qiangyuan Laser of SDIIT Ltd. (SDQY Laser) founded by Laser Institute of Shandong Academy of Science since 1978. A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, cutting, cladding machines and solutions.

Our products has exported to European, American, Middle Eastern, Australian, African countries and regions, we provided customers with high quality laser solutions. The professional quality and service in the laser industry market have establish a good brand image and reputation.

Keywords

Composite Laser Cleaning Machine

Contact Us

Classification