Equipment Introduction

Friction stir welding refers to the use of heat generated by the friction between the high-speed rotating welding tool and the workpiece to locally plasticize the material to be welded. When the welding tool moves forward along the welding interface, the plasticized material is affected by the rotational friction of the welding tool. It flows from the front to the rear of the welding tool, and forms a dense solid phase weld under the extrusion of the welding tool.

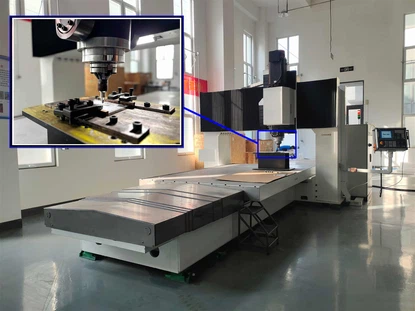

Gantry friction stir welding equipment is a stable and effective friction stir welding equipment with good market applicability. The workbench is arranged horizontally, and the columns and connecting beams on both sides form a gantry. The welding head is mounted on the cross beam and can move up and down along the guide rail.

Equipment Features

1. Non-melting, Solid Phase Welding

The welding of this equipment is realized in the plastic state of the material. The product weld has high metallographic consistency, and the weld has no thermal cracks, inclusions, pores and other welding defects.

2. Green, Environmentally Friendly, Healthy and Safe

The equipment does not produce smoke, spatter, ultraviolet rays and electromagnetic radiation during the welding process, making the welding process environmentally friendly.

3. Simplify the Welding Process and Save Costs

There is no need to perform special treatment on the oxide layer of the aluminum alloy before welding, nor to make grooves. There is no need for filling materials and protective gas during the welding process, which simplifies the welding process.

4. High Degree of Automation

Gantry friction stir welding uses automated mechanical equipment for welding, avoiding dependence on the technical proficiency of operators. Realized all-position welding automation.

5. High Reliability of Welds

Gantry friction stir welding has low residual stress in the weld, basically no deformation, the weld properties are close to the base material, and the mechanical properties are excellent. Improved weld reliability.

Performance Index

|

No. |

Equipment Name |

Main Performance Index |

|

1 |

Model |

FSW-LM-BL20-2D |

|

2 |

Table dimensions |

3500mmx2100mmx700mm |

|

3 |

Each axis stroke |

X : 3300mm Y : 2000mm Z : 500mm B:0~+5° C:+360 |

|

4 |

CNC system |

SINUMERIK-828D |

|

5 |

Frock |

Self-manufacture device |

|

6 |

Power |

25kw |

|

7 |

Welding thickness |

Aluminum alloy : 1 ~ 20mm Copper : 1 ~ 10mm |

|

8 |

Spindle speed |

0~2000rpm |

Application

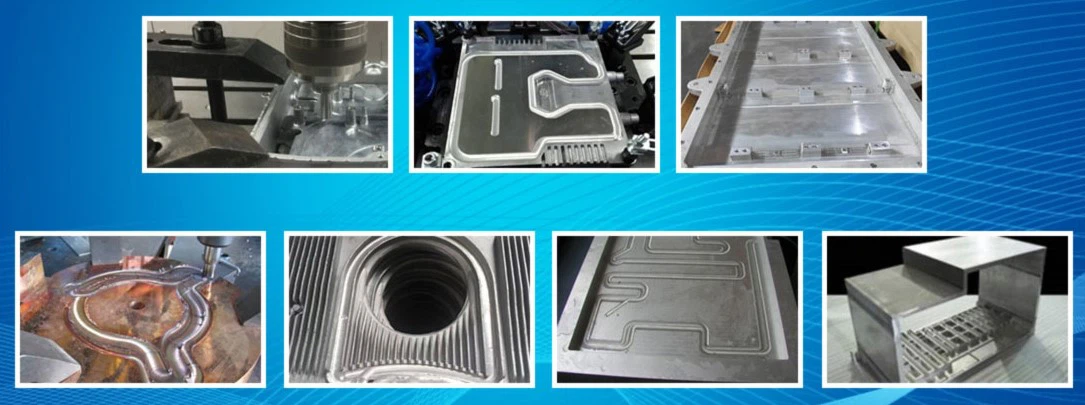

All kinds of aluminum profile splicing and planar two-dimensional curve welding can be realized.

Weldable aluminum alloy, copper alloy, magnesium alloy, qin alloy, steel alloy, high temperature material, etc.

Weldable new energy vehicle battery tray, water-cooled plate, motor shell, radiator, etc.

Applicable to aluminum alloy profiles, cold plate and cylinder welding.

It can be applied to batch welding of aerospace, rail transit, ship, automobile, power electronics and other products.

Company Profile

Shandong Qiangyuan Laser of SDIIT Ltd. (SDQY Laser) founded by Laser Institute of Shandong Academy of Science since 1978. A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, cutting, cladding machines and solutions.

Our products has exported to European, American, Middle Eastern, Australian, African countries and regions, we provided customers with high quality laser solutions. The professional quality and service in the laser industry market have establish a good brand image and reputation.

Gantry Friction Stir Welding Platform

Contact Us

Classification