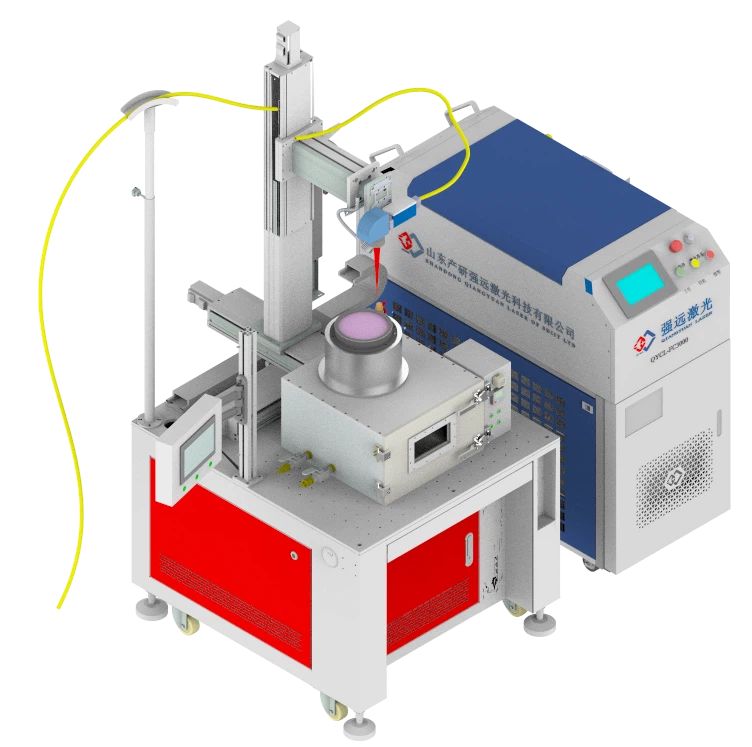

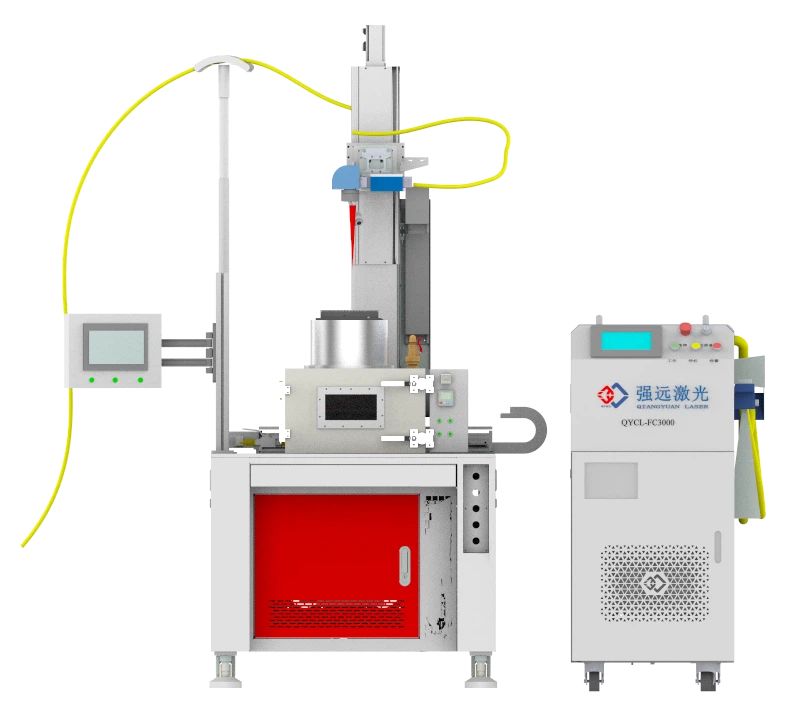

Precision Laser Vacuum Cleaning System for Cleaning Fine Metals or Easily Oxidized Materials

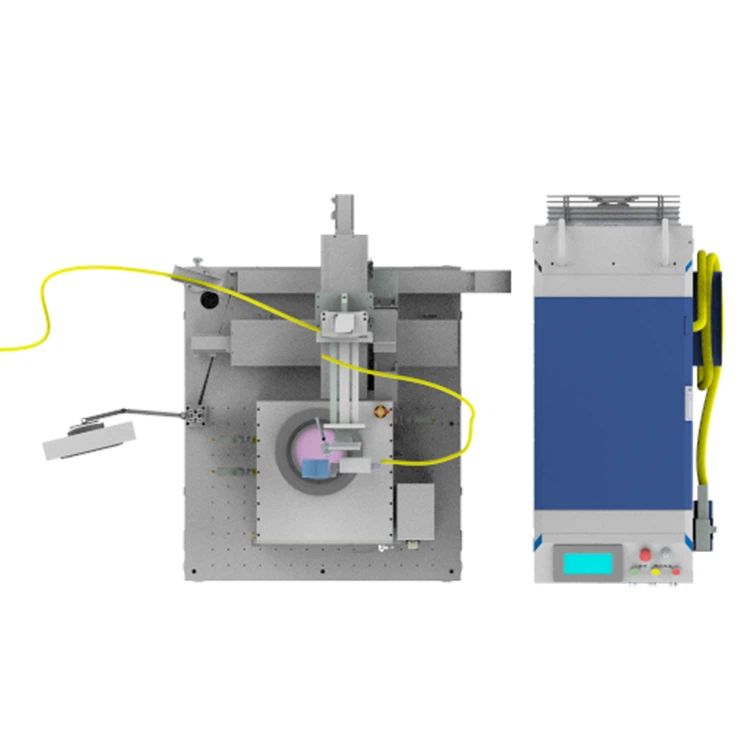

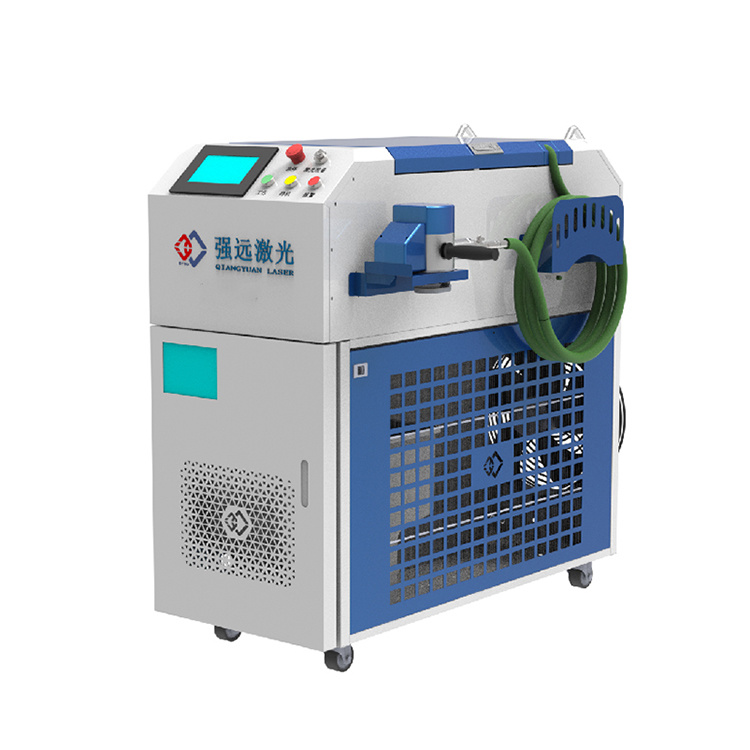

This product uses a QY-Precision Vacuum Cleaning series precision laser vacuum cleaning system that combines the QYHC18M-50 five-axis CNC operating system/CMTOS motion control system with the QYCL-FC3000 pulsed continuous laser cleaning system. This equipment is mainly used for metal, Surface rubber residues and ores are automatically cleaned or smelted. This laser device adopts dual laser cleaning and uses software-controlled light gates to integrate the cleaning width of its lasers. The end of the laser generator head is equipped with a safety lock and a blowing mechanism, and a professional laser chiller is used to cool the laser; the laser is integrated The result is that it is easy to replace and maintain, and the power adjustment range is 10%-100%; the vacuum box adopts a two-stage rotary vane vacuum pump with a small structure and beautiful appearance, and is specially designed for laser processing and metal processing machine tool configurations. The advantage is that automated cleaning reduces usage costs and labor costs. It has the characteristics of not damaging the workpiece substrate, high cleaning efficiency, and low labor intensity.

Advantages of Closed Vacuum Cleaning

1. Using a high-precision three-axis laser cleaning platform, it can meet the needs of laser cleaning of workpieces of different specifications and shapes;

2. Equipped with a rotating platform that can rotate at any angle 360° to facilitate workpiece cleaning;

3. The end of the cleaning head is equipped with a safety lock and air blowing mechanism;

4. The angle of the laser temperature measurement device can be adjusted

5. Equipped with a precision rotating platform, laser temperature measurement control system, and digital display air pressure instrument.

6. The stepper precision rotating platform has higher accuracy and less impact on quality, thus ensuring the quality of the products being cleaned.

7. Sealed inert gas cleaning can further reduce the oxidation of the workpiece, reduce the contact between raw materials and oxygen, and the cleaning effect is more obvious.

8. Built-in pushing mechanism to automatically push materials into the water tank after cleaning.

9. There is a pneumatic door between the water tank and the vacuum cleaning tank. When the material falls, the discharge door opens in advance and can be closed automatically after the material passes through.

Technical Specification

Sample

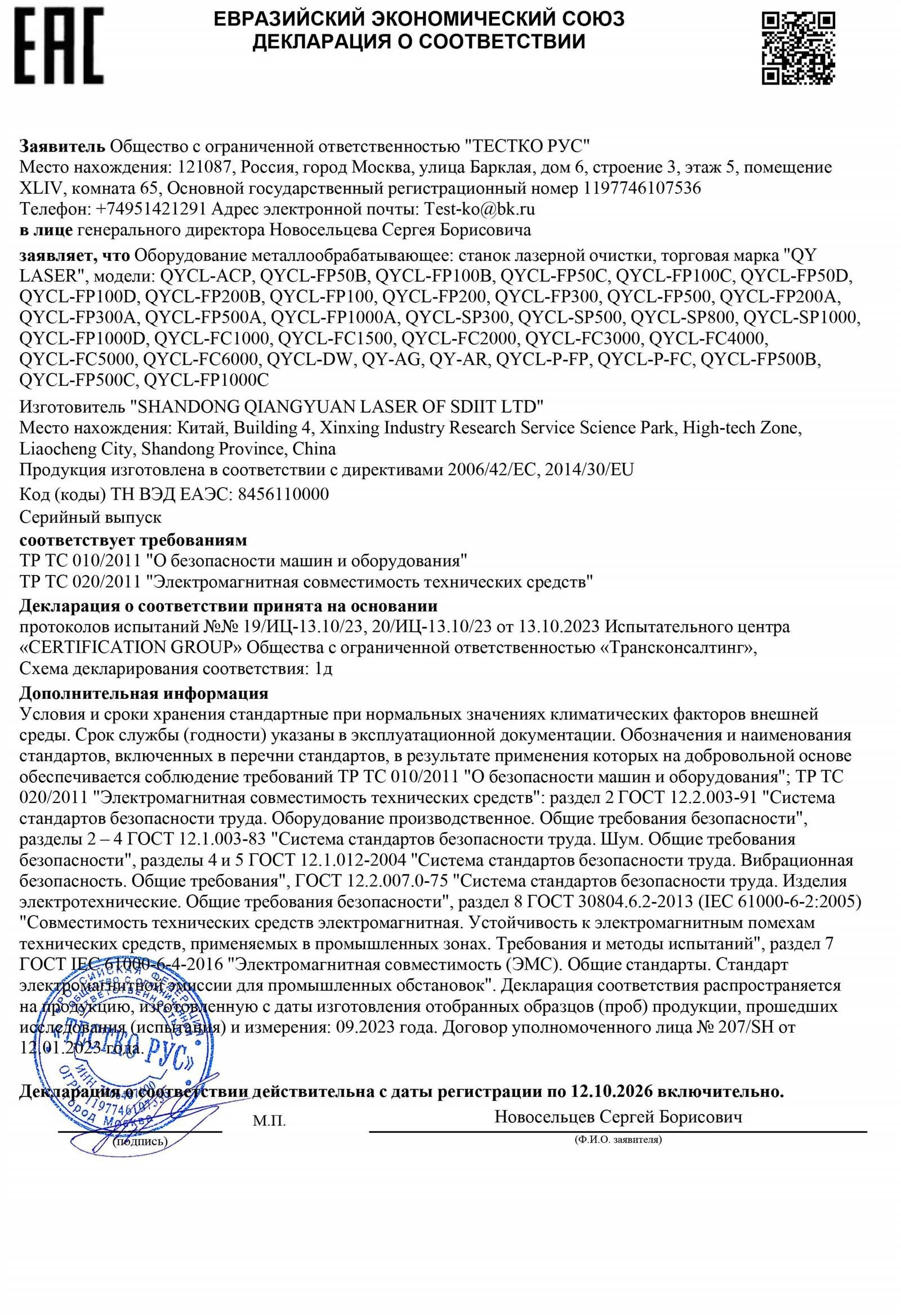

Certificate

Company Profile

Shandong Qiangyuan Laser of SDIIT Ltd. (SDQY Laser) founded by Laser Institute of Shandong Academy of Science since 1978. A leading enterprise focusing on the R&D, manufacturing, sales and service of laser cleaning, welding, cutting, cladding machines and solutions.

Our products has exported to European, American, Middle Eastern, Australian, African countries and regions, we provided customers with high quality laser solutions. The professional quality and service in the laser industry market have establish a good brand image and reputation.

Keywords

Precision Laser Vacuum Cleaning System

Contact Us

Classification