Laser Cleaning Machine Remove Film

Jan 23,2026

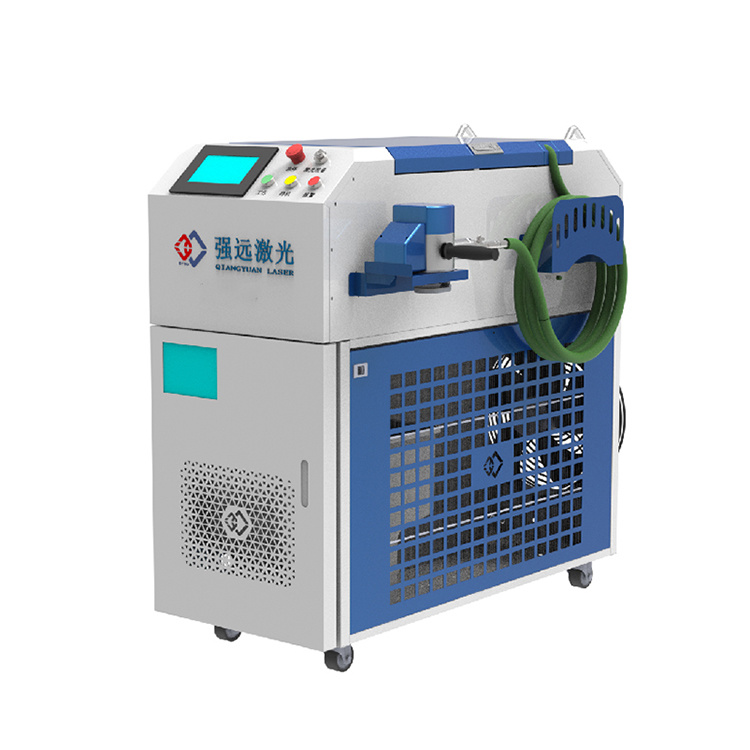

In precision manufacturing and high-tech maintenance, removing contaminants without damaging delicate substrates is a major challenge. SDQY laser cleaning systems offer an industry-leading non-contact solution for selectively removing thin films such as oil, grease, oxides, and coatings from sensitive optical, electronic, and precision mechanical components.

Why Choose SDQY Laser Cleaning Machines?

1. Substrate-Friendly: Adjustable laser parameters selectively remove contaminants while protecting the underlying surface, coatings, and functional integrity.

2. Wide Range of Applications: Suitable for cleaning precision optical components, semiconductor devices, medical devices, aerospace parts, and complex machinery requiring extremely high cleanliness.

3. Environmentally Friendly and Pollution-Free: Requires no chemical solvents, abrasives, or water, eliminating wastewater and exhaust emissions, meeting green manufacturing standards.

4. Long Lifespan and Low Maintenance Costs: The main cost is electricity, and the laser lifespan reaches 100,000 hours. Maintenance is simple, requiring only periodic lens replacement.

Related Products

Laser cleaning technology helps maintain the efficiency and lifespan of high-precision components, making laser cleaning machines an essential tool for industries with extremely high surface cleanliness requirements.

PREVIOUS:

Related Posts