Laser Cleaning Welding Burns

Jan 16,2026

Laser cleaning technology can efficiently remove welding marks from metal surfaces. This method is particularly suitable for welded joints and machined metal parts, removing discoloration and burn marks without damaging the material, ensuring a clean and professional surface.

Welding burn, typically manifesting as discoloration or marks left after welding, affect the appearance and integrity of metal surfaces. Our laser cleaning service offers a precise solution that removes these marks while preserving the quality of the metal. Regular use of our laser cleaning service is crucial for industries involving welding, as it helps maintain the aesthetics and structural integrity of welded components, providing an efficient and non-destructive alternative to traditional cleaning methods.

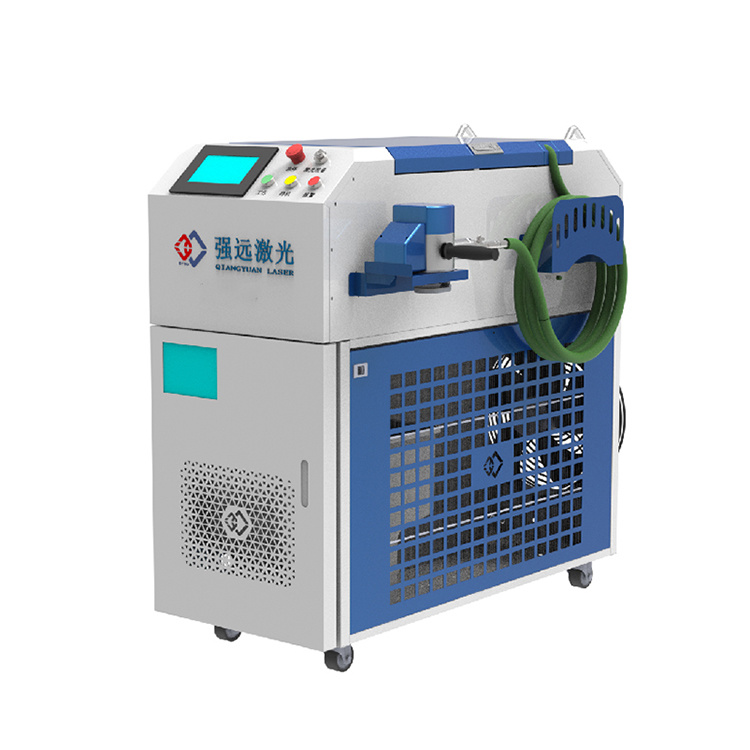

Applicable Products

Benefits of Laser Cleaning Welding Burns

1. Non-destructive Precision Cleaning

Laser cleaning can precisely remove weld burn marks, heat stains, and oxides. It targets only the affected surface layer, preserving the substrate's structure, surface finish, and mechanical properties without grinding or abrasion.

2. No Chemical Additives, Environmentally Friendly Process

Laser cleaning requires no acids, solvents, or consumables. This not only avoids the generation of hazardous waste and reduces environmental impact, but also helps manufacturers maintain a cleaner production environment while meeting stringent environmental and workplace safety regulations.

3. Improving Welding Quality and Corrosion Resistance

Laser cleaning can thoroughly remove oxide layers and heat-induced discoloration, restoring the passivation layer of the metal. This significantly improves corrosion resistance, especially for stainless steel, and enhances the overall quality and service life of welded components.

4. Reduced Operating and Maintenance Costs

Unlike traditional methods, laser cleaning minimizes consumables, labor, and rework. Due to low maintenance requirements and a long service life, laser cleaning machines for weld burn marks reduce total operating costs and increase return on investment.

5. Highly Efficient and Easily Automated

Laser cleaning technology enables rapid, repeatable cleaning results and can be easily integrated into robotic arms or automated production lines. This not only improves production efficiency and ensures consistent product quality but also supports high-volume industrial welding applications.

6. Improved Workplace Safety and Operator Comfort

Non-contact processes reduce dust, noise, sparks, and hand fatigue. Operators will benefit from a safer, cleaner working environment, and businesses can improve compliance with occupational health and safety standards.

Application Cases

PREVIOUS:

NEXT: