Advantages of Top-Hat/Flat-Top Laser Cleaning Machine

Mar 11,2025

Most laser beams are Gaussian, but in some cases it may be beneficial to have a non-Gaussian irradiance profile. The symmetric irradiance distribution of a Gaussian beam decreases as the distance from the centre of the laser beam cross-section increases. Flat-top or top-hat beams have a constant irradiance distribution across the cross-section of the laser beam (Figure 1). Some applications that benefit from constant intensity over a given area include the processing of semiconductor wafers, nonlinear frequency conversion at high power levels, and materials processing. Flat-top beams typically produce more accurate and predictable results, such as crisper cuts and sharper edges, than Gaussian beams, but they come with additional system complexity and cost.

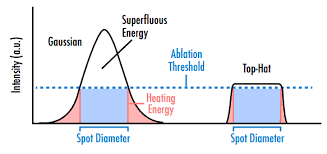

Figure 1: Gaussian beams waste energy through both superfluous energy higher than the threshold required for the application and energy lower than the threshold in the outer portions of the gaussian beam. Top hat/flat top beams are more efficient in that they surpass the threshold while minimizing wasted energy.

Gaussian beams

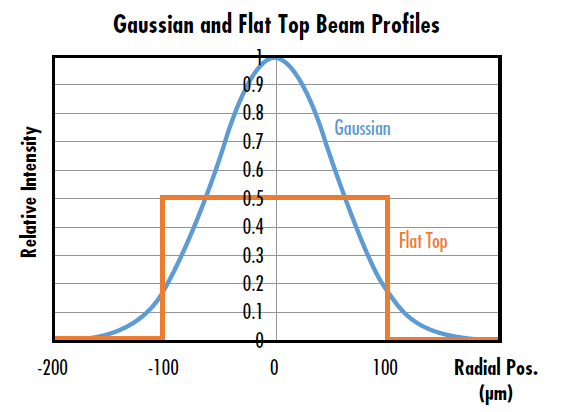

High-quality single-mode lasers produce a low-order gaussian irradiance distribution, the TEM00 mode. A gaussian beam with the same average optical power as a top hat/flat top laser beam has twice the peak energy density of a top hat/flat top laser beam (figure 2). The gaussian beam remains constant under transformation; therefore, as the beam propagates through the system, the beam profile remains gaussian distributed even if the beam size changes. This is because the fourier transform of a gaussian function is another gaussian function. Light undergoes a fourier transform by propagating to infinity or by focusing through a perfect lens. To learn more about laser modes such as the TEM00, visit our laser resonator mode application note.

Figure 2: Gaussian and flat top beams at the same optical power, showing the peak intensity of the Gaussian beam is double that of the flat top beam.

Gaussian lasers are more common and cost-effective than other lasers, but they have several drawbacks, such as their "wings" or low-intensity regions extending from the usable centre of the beam. If the intensity of the wings of a Gaussian beam is below the threshold required for the application, this usually results in wasted energy (Figure 1). They also cause damage to the surrounding area and extend the heat affected zone, which can be detrimental to applications such as laser surgery and precision materials processing. Cutting or shaping fine features with a Gaussian beam results in less precision than with a top hat/flat top beam due to the larger heat-affected zone of the beam, making top hat/flat top beams a better choice for such applications.

Top Hat/Flat Top Beams

One way to evaluate how close a real beam is to an ideal flat top beam is by the flatness factor (Fη). This is determined by dividing the average irradiance value by the maximum irradiance value as described.

Fη=Average Irradiance / Maximum Irradiance

The absence of wings and steeper edge transitions in top hat/flat top beams allows for more efficient energy transfer and a reduced heat-affected zone. This is beneficial for a wide range of applications where high accuracy and minimising damage to the surrounding area is a priority. In metrology applications such as laser-induced damage threshold (LIDT) testing, the uniform and well-defined profile of a top hat/flat top beam reduces measurement uncertainty and statistical variance.

Top hat/flat top beams are not as cost-effective as Gaussian beams because an additional beam shaping component is required to convert the laser output to a top hat/flat top beam (Figure 3). This beam shaping component can be built into the laser source or placed outside the laser. These additional beam shapers are sensitive to x-y alignment and depend on the input beam diameter. The top hat/flat top laser beam does not remain constant under transformation. Therefore, the beam profile of the incident top hat/flat top beam is not naturally preserved as the beam propagates. The Fourier transform of the top hat/flat top function is an Airy spot function, which means that the top hat/flat top beam will eventually evolve into an Airy spot.

Figure 3: Animation of a beam profile converting between a Gaussian distribution and a flat top distribution.

The use of high-hat/flat-hat laser beams offers a range of benefits for a variety of industrial and scientific applications. With its uniform energy distribution and ability to reduce thermal lensing and spot size, this type of beam can help improve the precision, consistency and effectiveness of many different laser processes.

SDQY Laser is a laser cleaning machine factory with technical strength. We have a professional R&D team to provide customers with high-quality, high-performance laser cleaning equipment, including 200w, 300w, 500w top-hat/flat-top beams and 100w 200w 300w 1000w Gaussian beam laser cleaning machines. At the same time, we can also provide customized automatic laser cleaning solutions according to customer needs to meet the different needs of customers.

In the future development, we will continue to uphold the principle of "quality first, service first", continuously improve the quality of products and services, and provide customers with better laser cleaning solutions. Welcome customers from all walks of life to contact us and create a better future together!

PREVIOUS: