Laser Cleaning Machine for Paint Removal

Mar 14,2025

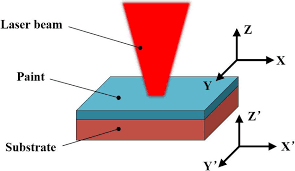

Laser paint removal is an environmentally friendly process used to remove paint layers from metal surfaces without damaging the substrate. It’s also known as laser coating removal and de-coating.

Laser paint removal works with a process called laser ablation, which is when a laser beam delivers sufficient energy to ablate the coating. As the paint is vaporized, the metal surface is left intact.

To achieve ablation, the laser energy is released in short pulses and at a set repetition rate. As a result, the pulsed laser generates shockwaves that eject coatings when they reach their ablation threshold. One of the benefits is the ability to remove coatings from precise areas.

The laser ablates the coating without damaging the metal underneath. When using a single-mode fiber laser, the laser can texture the base metal at the same time if needed. When using a multimode fiber laser, the process cannot texture the metal surface, but it can reach faster cleaning speeds.

Why Choose Laser Technology For Paint Removal?

Manufacturers in the automotive industry spend a lot of time and labor masking parts. This slows down the coating process and often leads to quality issues.

Laser paint removal is much more effective and can be integrated inline in high-volume automated productions—without slowing them down. All you need to do is coat the entire part, then use the laser to remove paint from specific areas.

With its micron precision, laser cleaning can strip paint and other contaminants from specific areas without touching or damaging the rest, making it ideal to prepare high-quality parts for welding or assembly. It represents an alternative to processes like sandblasting for paint stripping applications that demand high precision.

Damaging metal surfaces while removing paint is costly. It can increase your scrap rate or diminish the quality of your parts. Unlike other paint removal methos, laser surface cleaning is a non-contact process fine-tuned to remove paint without affecting the metal.

Laser paint stripping is a great solution for high-volume productions. As opposed to abrasive blasting and manual masking, laser cleaning can be completely automated and doesn’t need maintenance between parts. As a result, paint removal does not become a bottleneck in your production line.

Some paint stripping methods have more security risks than others. Laser cleaning is a lot simpler to implement than mechanical and chemical alternatives and has fewer risks. You only have to manage fumes.

The process can be applied to any metals, although the most typical are steel, aluminum and copper. It can be used for different types of coatings, including powder coating, e-coating, phosphate coating, and insulating coating. Laser cleaning can also be used for similar applications such as laser rust removal, oxide removal, mold cleaning, and surface preparation.

PREVIOUS: